Together, we are shaping the coming era of manufacturing.

Order turned parts conveniently online and have them manufactured in your turning shop

Uncomplicated online ordering of CNC turned parts. Fast processing with attractive conditions. Free test certificate included with every order. Upload your CAD file and receive a quotation within 48 hours.

1.000+

Customers

2.000+

Maschinen

0,12%

Complaint rate

What characterises our CNC turned parts?

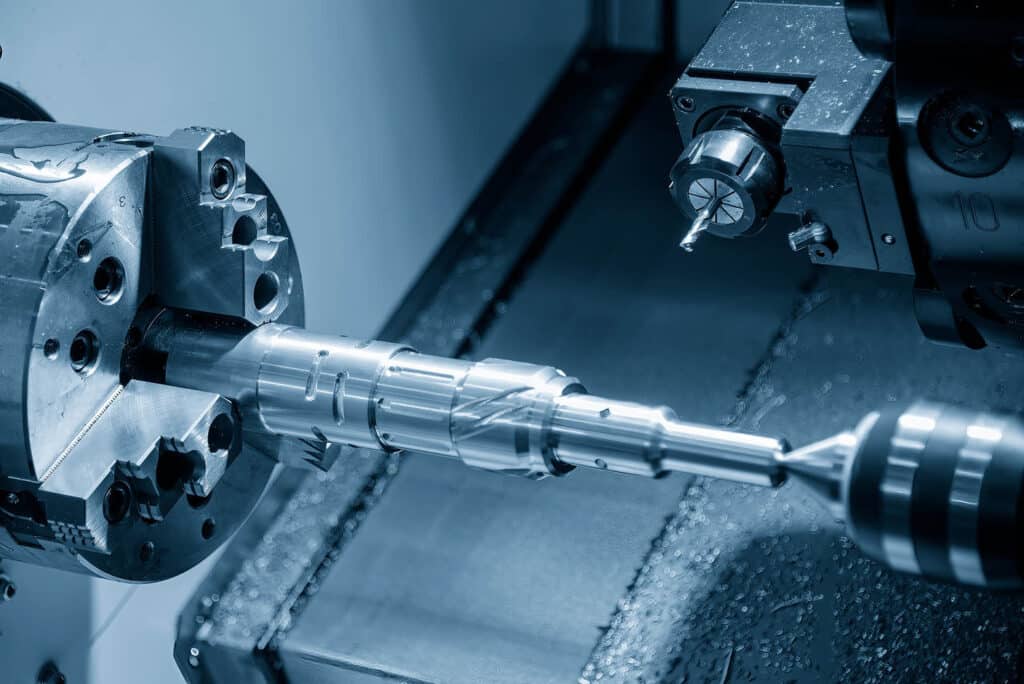

Part of our basic understanding is the continuous investment in our machine infrastructure. Because this is the only way we can ensure the valued quality and precision in contract manufacturing. In the field of CNC turning (Computerised Numeric Control), we rely on automatic lathes and sliding headstock lathes. Our CNC machines enable us to machine long turned parts and precision turned parts with workpiece diameters of 3 to 600 mm and lengths of up to 2000 mm.

In addition to this equipment, we have conventional CNC lathes and automatic lathes for single part production and repair work in CNC turning. With these, we can machine turned parts up to a diameter of 400 mm and a maximum length of 1000 mm.

Outstanding advantages of CNC turning at Streametal

As soon as our non-binding offer meets your expectations and we receive your order, we immediately proceed to the production of your turned parts. Depending on the requirements and the task, either our CNC machines or the corresponding conventional variants are used. Our team is perfectly proficient in both the common CNC controls and the operation of manual lathes. In this way, your individual parts or series productions are always machined by specialists.

In contract manufacturing, we take on orders from a batch size of 1 piece. There is practically no upper limit. The production of assemblies is also within our area of expertise. Thanks to our stock of lathes, milling machines and a sheet metal working department, we can offer you ready-to-assemble production and assembly of even the most complex workpieces and components.

Our products bear the “Made in Germany” seal of quality at extremely competitive prices. We achieve this through efficient manufacturing and state-of-the-art management software that keeps our operating costs low.

CNC turning

Technical data

Diameter:

Length:

Tolerances:

Surface roughness:

Materials:

Lot sizes:

1 mm – 5.300 mm

0.5 mm – 20,000 mm

bis +/- 0.05 mm

bis Ra 0.8 / Rz3.2

Über 600 Werkstoffe

ab 1 Stück

Our materials

Available materials

Aluminium

Bronze

Cast iron

Stainless steel

Steel

Hard fabric

Inconel

Ceramics

Plastics

Copper

Brass

Titanium

other materials on request

Our manufacturing processes

Your components in 3 steps

1

.......................

Submit an enquiry

Simply upload your production drawing and specify the order. You will receive a quotation from us within 48 hours.

2

.......................

Quality control

Our service includes finding the right manufacturer, monitoring production and carrying out quality controls – all from a single source.

3

Components received

After successful quality control, you will receive your components from us, accompanied by a detailed test certificate.

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Turned part production

How does the production of CNC turned parts take place?

As soon as you are satisfied with our non-binding offer based on the drawings provided and place the order with us, we will immediately start manufacturing your CNC turned parts. Depending on the requirements and the nature of the task, we decide whether to use our CNC machines or the corresponding conventional processes for production. Our team is proficient in both the common CNC controls and the operation of manual lathes, so that your individual parts or series production are always machined by experienced specialists.

In contract manufacturing, we take on orders from a batch size of 1 piece, and there are hardly any limits upwards. Please note that we are not a B2B marketplace, but work with a carefully selected partner network. Every manufacturer of turned parts in our network is regularly audited. Our quality management is certified according to DIN ISO 9001:2015 (DIN EN ISO).

Material selection

Which materials are suitable for machining on lathes?

In addition to conventional machining materials such as steel, stainless steel, free-cutting steel and aluminium, our range of services naturally also includes the machining of materials such as copper, brass and plastics. We are also able to process special materials such as high-alloy steels for you after prior consultation.

Our expertise is not limited to the turning of workpieces. We also offer extended assembly services and the coating of manufactured assemblies.

Do not hesitate to contact us about our possibilities. We are already looking forward to your contact!

Our manufacturing processes

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

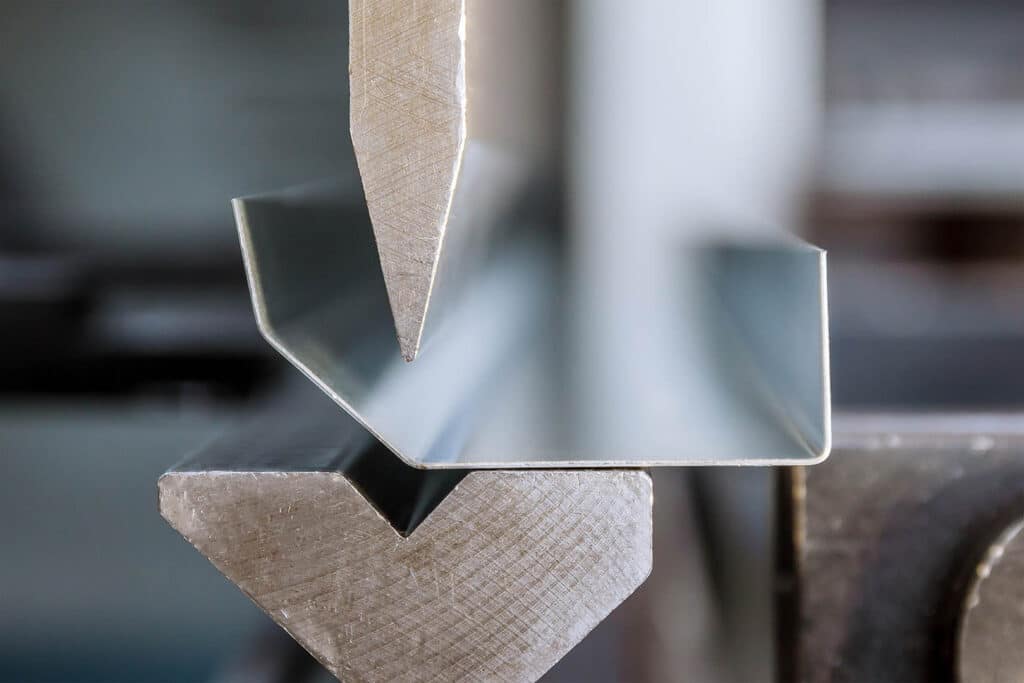

Bending

Punching

Laser cutting

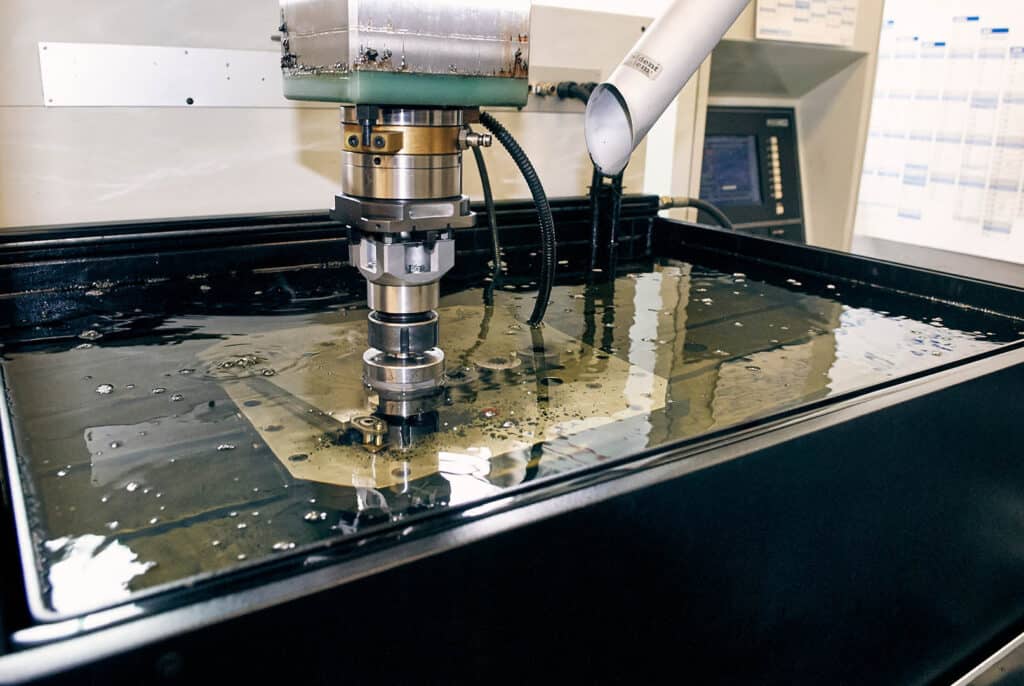

Water jet cutting

Eroding

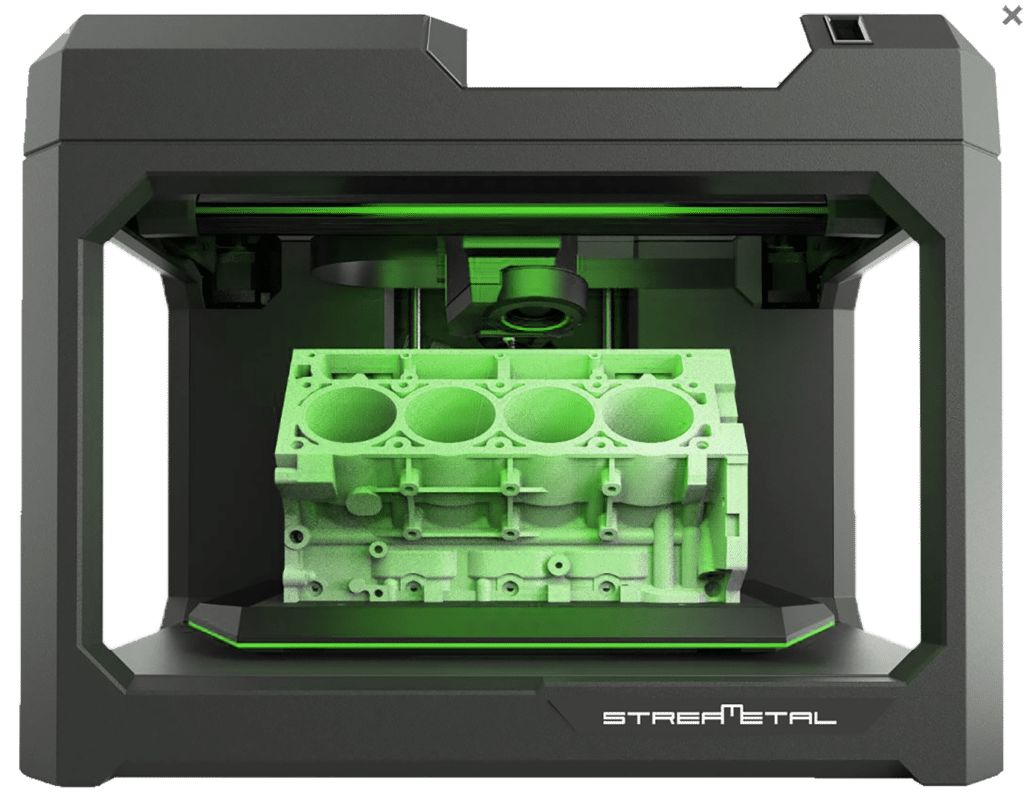

3D printing

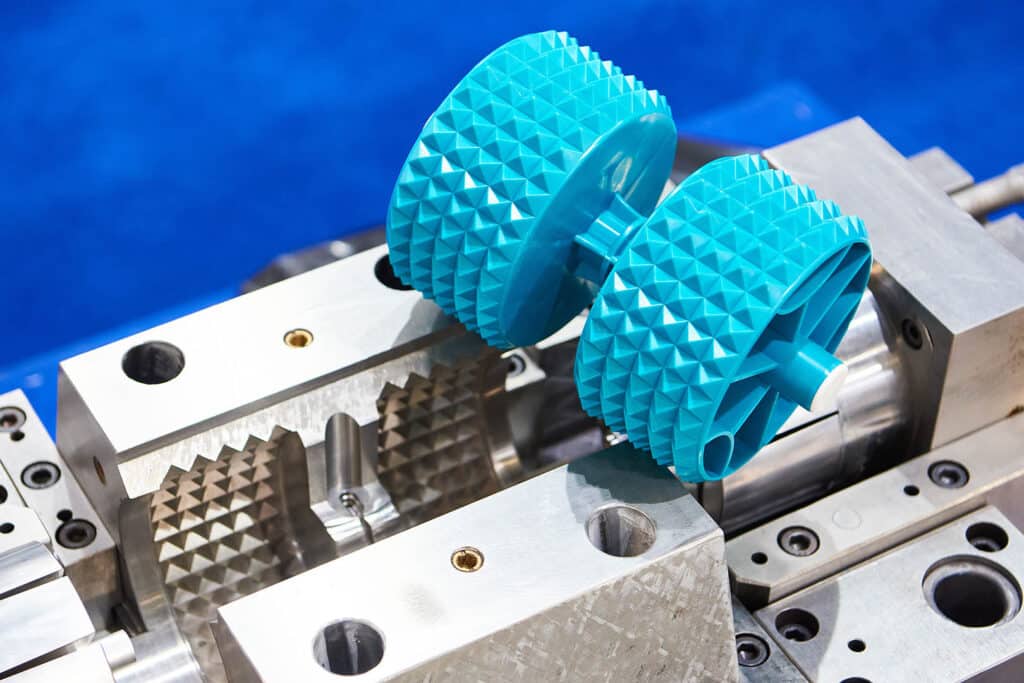

Injection moulding

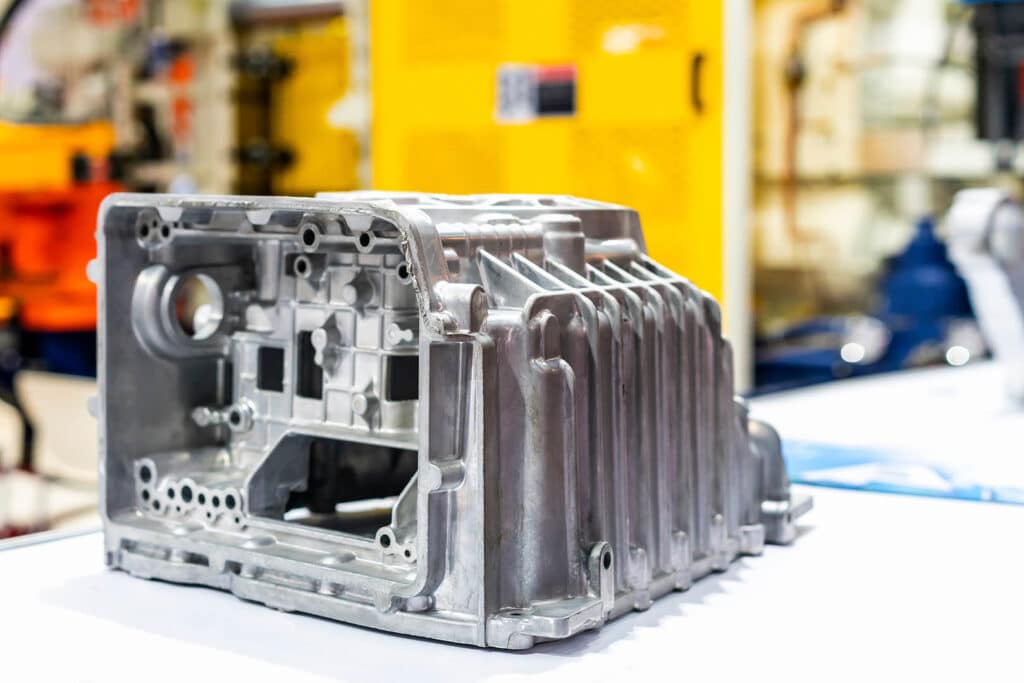

Die casting

Surface treatment

Sheet metal working

Here you will get an overview of all working steps of the CNC turning process.

Preparation phase

1. preparation of semi-finished products

Cutting techniques such as sawing, laser cutting, flame cutting or water jet cutting are used to prepare the starting material for turning, i.e. the semi-finished products.

Set-up time

2. setting up the machine

To set up the machine tool for the production of the turned part, all the required semi-finished products as well as turning and milling tools are attached. This process is accelerated by experienced and highly qualified specialists.

Programming

3. creation of the CNC programme

The production programme (NC programme) instructs the CNC machine how to produce the final product from the semi-finished products using the tools. In modern computer-controlled system environments, programming is done with the help of CAM software.

Manufacturing

4. manufacturing parts

After set-up, the actual CNC machining takes place in primary and secondary phases. Primary phases, such as material removal, can occasionally take more time. Secondary times, such as tool changes on CNC lathes, are kept short.

Streametal's ambition is to be the leading platform for CNC manufacturing in Europe.

Through Streametal, the procurement of CNC turned and CNC milled parts is simplified.

Streametal is at your disposal as an expert and contact for prototypes, single pieces, small series and also larger quantities. Our expertise in CNC turning and CNC milling, our own manufacturing experience, a Europe-wide network of partners and quality management according to DIN EN ISO 9001:2015 make us your reliable partner.