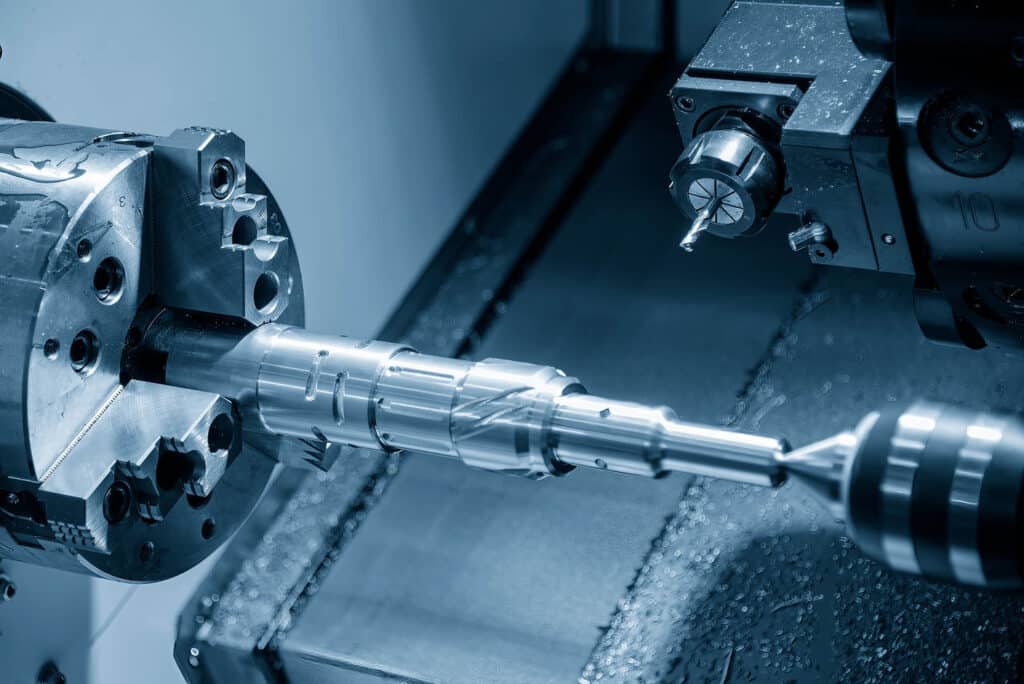

Machining with maximum accuracy.

Precision parts

- We only receive pre-qualified enquiries at 100%.

- Our service is free of charge for manufacturing partners.

- Profit from more orders and generate additional turnover.

1.000+

2.000+

Maschinen

0,12%

At Streametal, precision parts are a matter of trust in quality.

Our experts at Streametal are dedicated to producing CNC precision parts of the highest quality. For us, quality is not just a customer expectation, but a true mission. Our goal is to always exceed our customers’ expectations. We understand the critical importance of maintaining tolerances, surface finishes and other specifications that are essential to the success of a production.

Therefore, trust our competence and experience in the field of precision parts to successfully implement your project.

Welcome to Streametal- your expert for the production of demanding CNC precision parts.

Thanks to our state-of-the-art CNC machines, we at Streametal can produce almost any shaped workpiece in any desired quantity. Our mission is to ensure consistent quality, strictly in accordance with our customers’ specifications.

Our company policy of focusing on quality and service has so far delighted every one of our customers. The successful processing of numerous orders has provided us with valuable experience that equips us for future challenges.

Our machinery consists of modern automatic lathes and milling machines with which we can produce your precision parts in any contour. We always keep our machinery at the cutting edge of technology so that we can also push into ever tighter tolerance ranges.

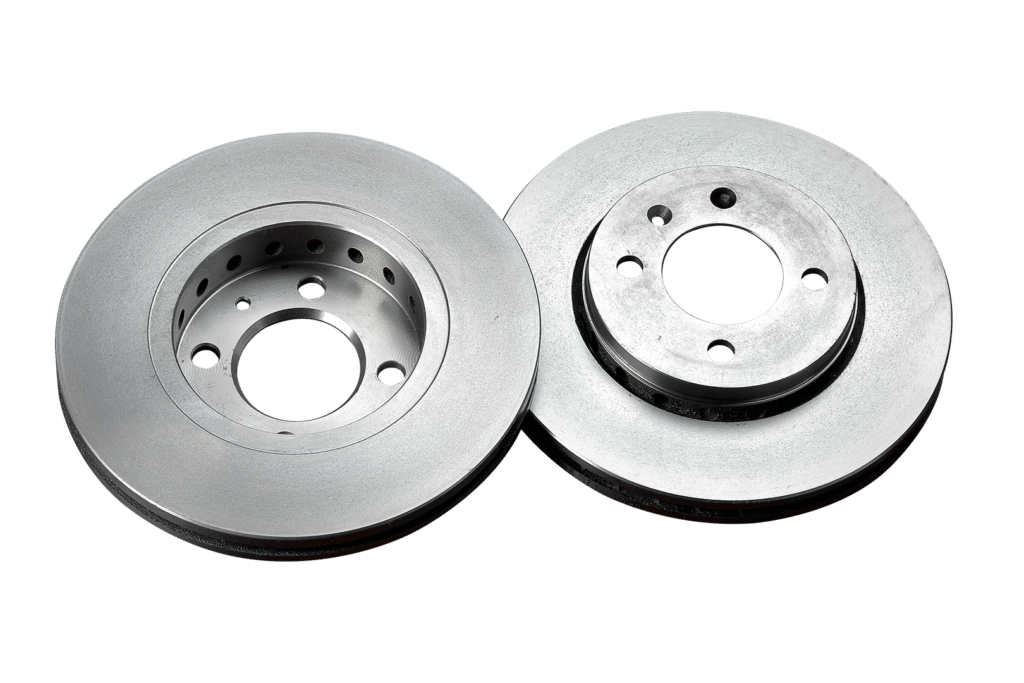

Thanks to these technological capabilities, we are already a leading supplier for demanding industries such as the automotive industry, special machine construction, aerospace and medical technology.

Our manufacturing processes

Your components in 3 steps

1

.......................

Submit an enquiry

2

.......................

Quality control

3

Components received

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Your advantages

Highest quality & service for your precision parts.

Are you curious? Simply let us know your request regarding your precision parts via our contact form. The more precisely you describe your project, the more accurately we can provide you with a preliminary quotation.

It only takes a short time from your enquiry to the quotation. Our focus is on service and transparency. Together we will discuss the details of your precision parts in a follow-up meeting to clarify any questions.

Our company is ready for the challenges of Industry 4.0. Send us your digital plans and let us inspire you with our performance. Our goal is to win you as a long-term satisfied customer.

Material selection

Which components and materials are suitable for machining?

Our extensive machinery and our experienced engineering team cover the entire spectrum of materials commonly used in mechanical engineering.

We not only offer the production of precision parts from semi-finished products and blanks, but are also happy to take on the further processing of existing finished products.

Our high-precision surface processing ensures that every product achieves the desired dimensions and meets the quality requirements.

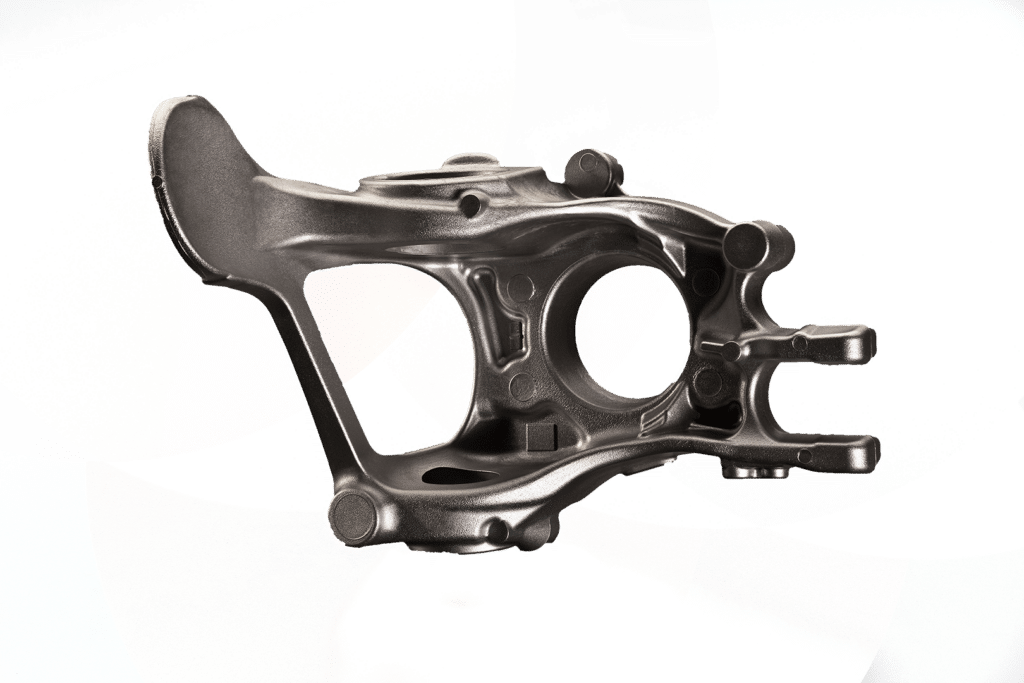

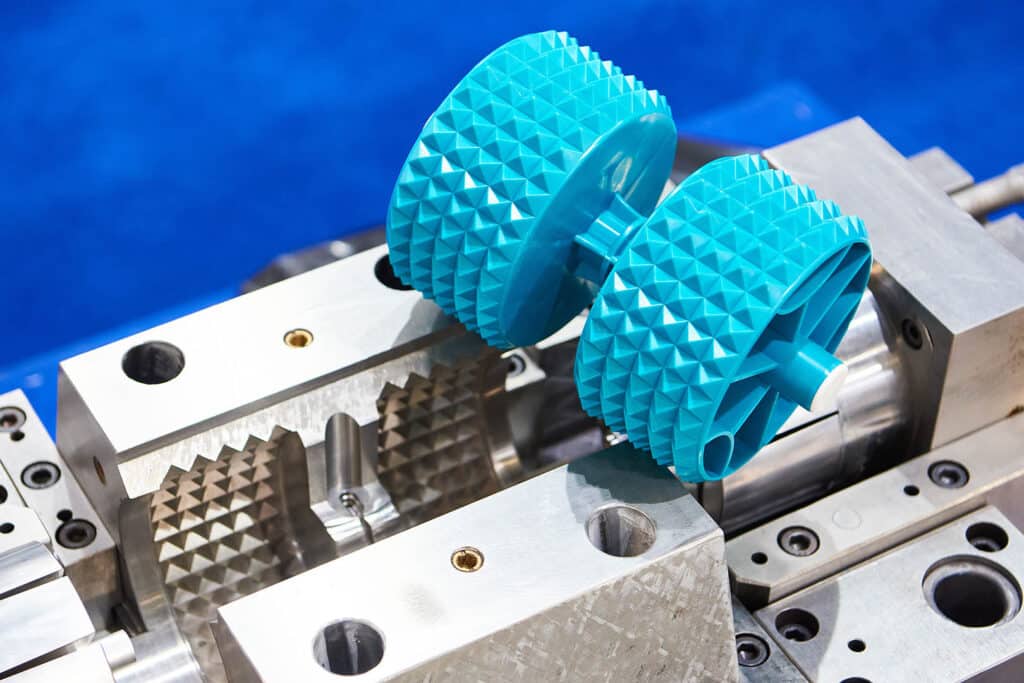

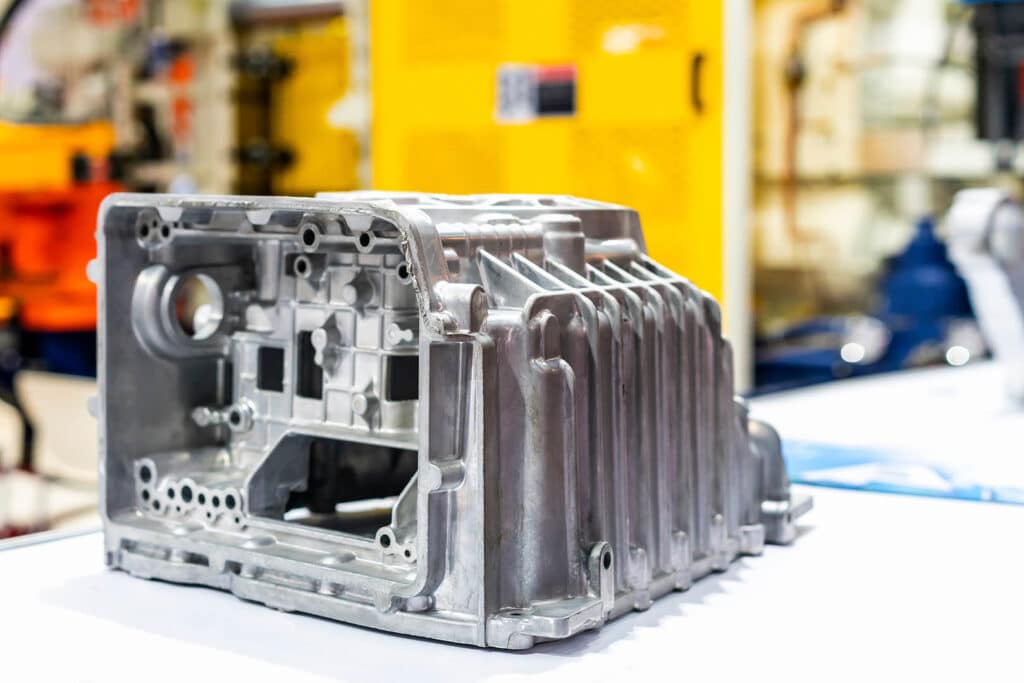

What we produce

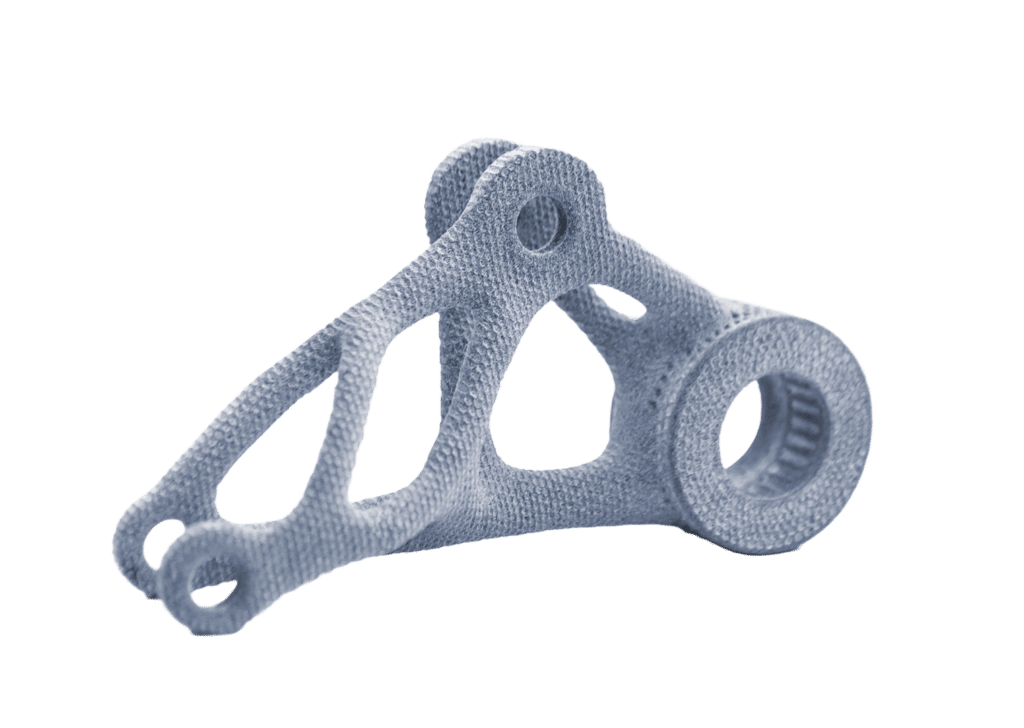

Sample components

Surface processing

We maximise the potential of your components

- Sandblasting

- Painting

- Anodising

- Powder coating

- Electroless nickel plating

- Galvanising

- Passivating

- Chromating

Our manufacturing processes

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

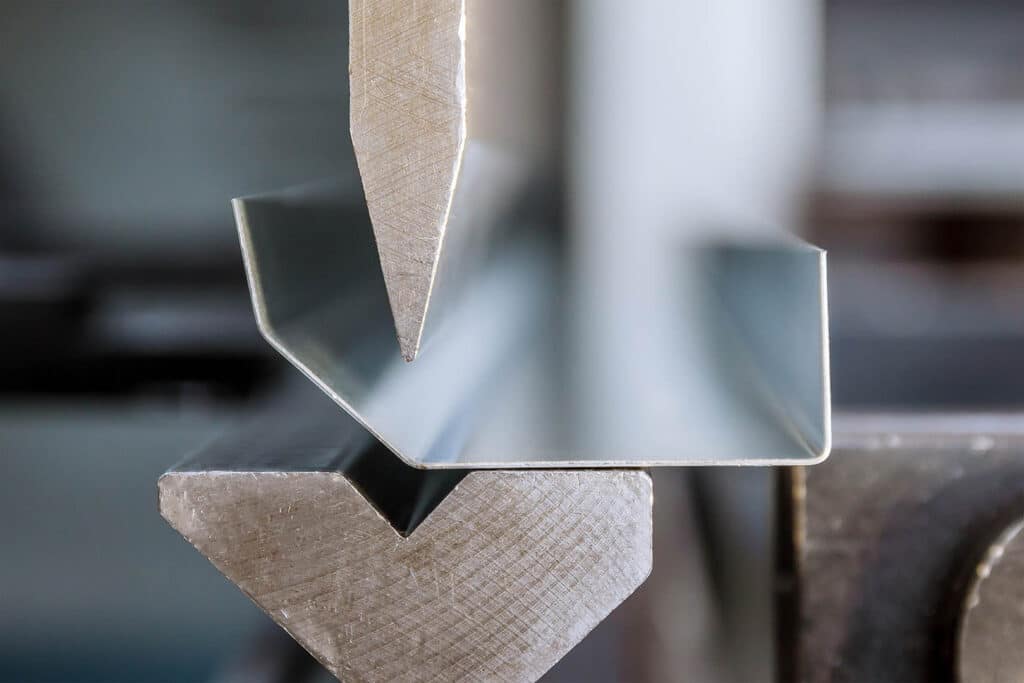

Bending

Punching

Laser cutting

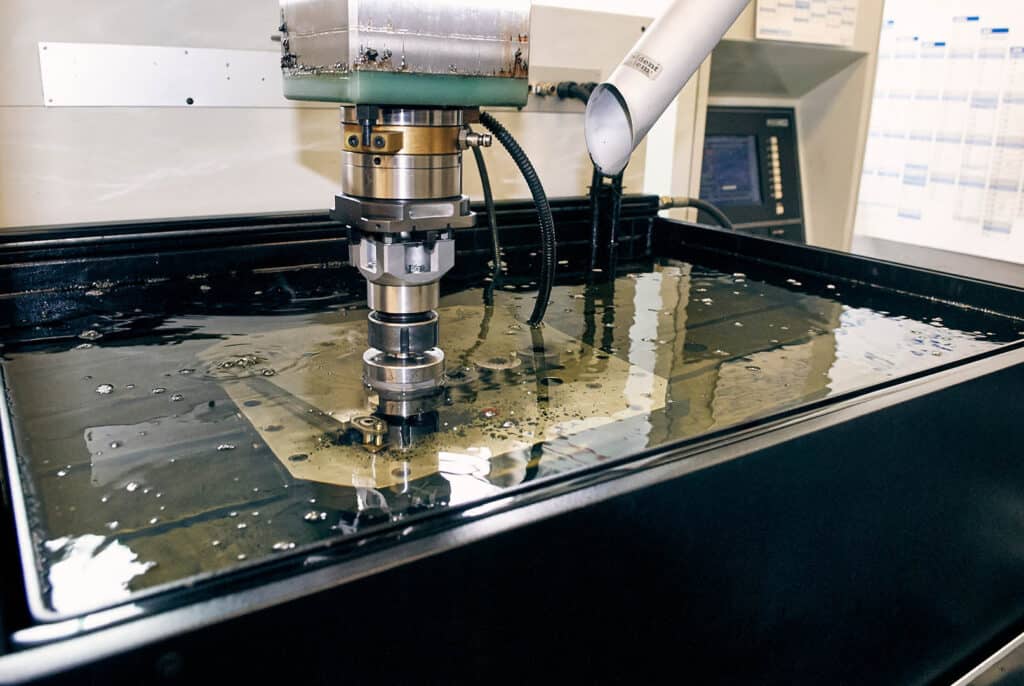

Water jet cutting

Eroding

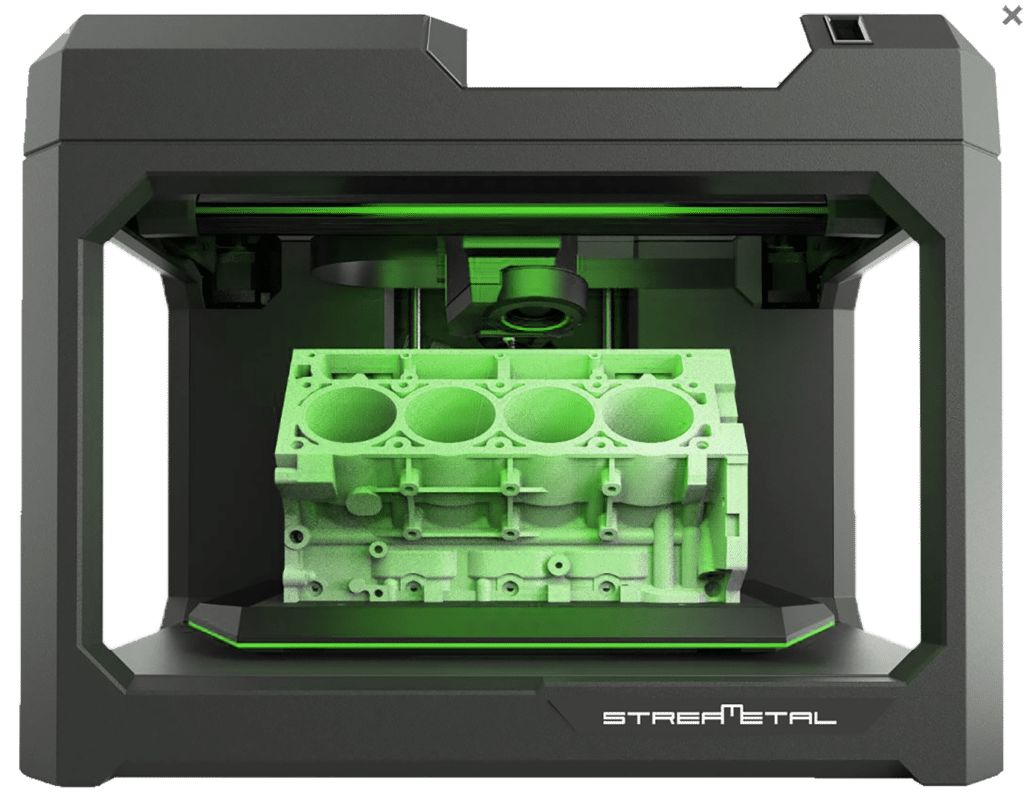

3D printing

Injection moulding

Die casting

Surface treatment