CNC express production

When it is extremely urgent

Smooth processing

For an accelerated production we need the following information:

Drawing as PDF and/or 3D

Desired number of pieces

Material and, if necessary, alternative materials

Additional surface treatment

Desired delivery time

Contact for queries during the entire production period

Delivery address for the components

Required certificates

This is how the Express Service operates.

Your components in 3 steps

2

.......................

Release order

3

Delivery

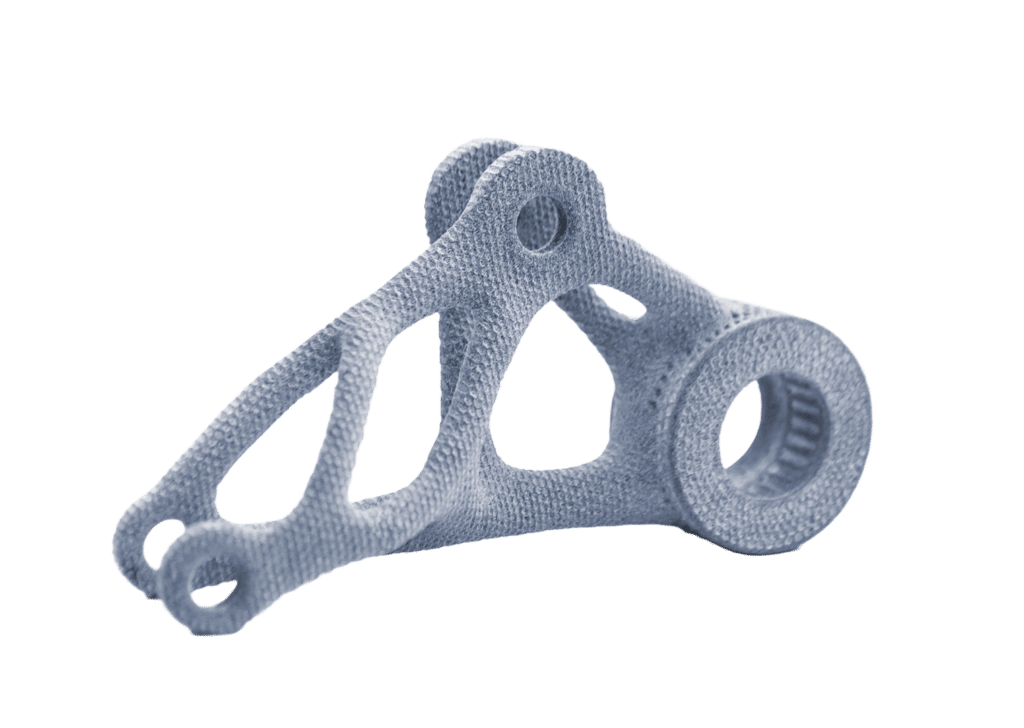

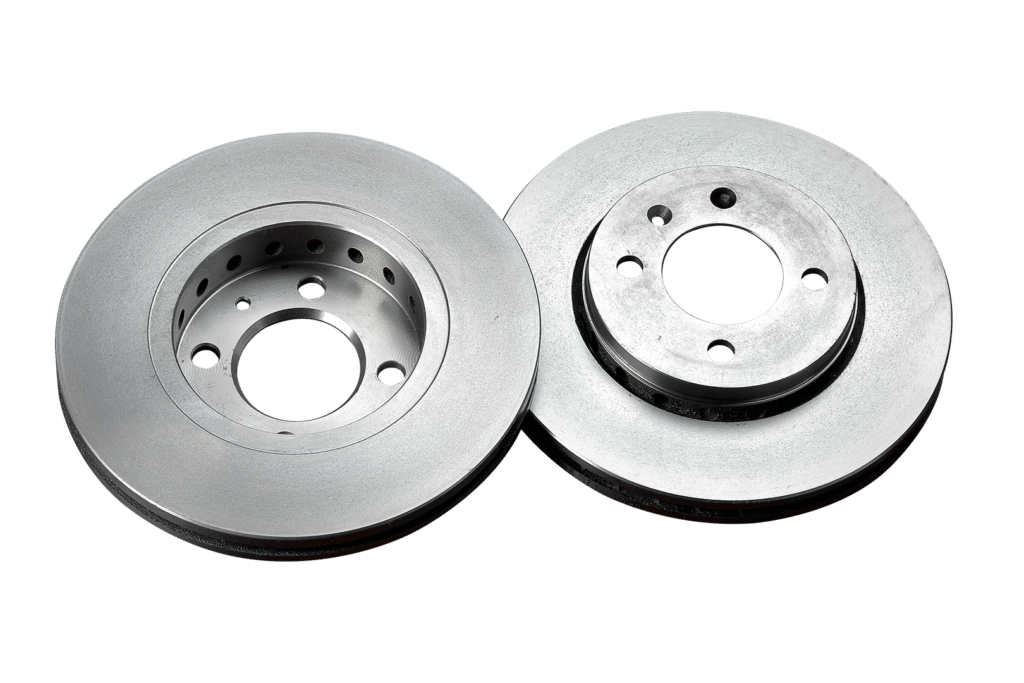

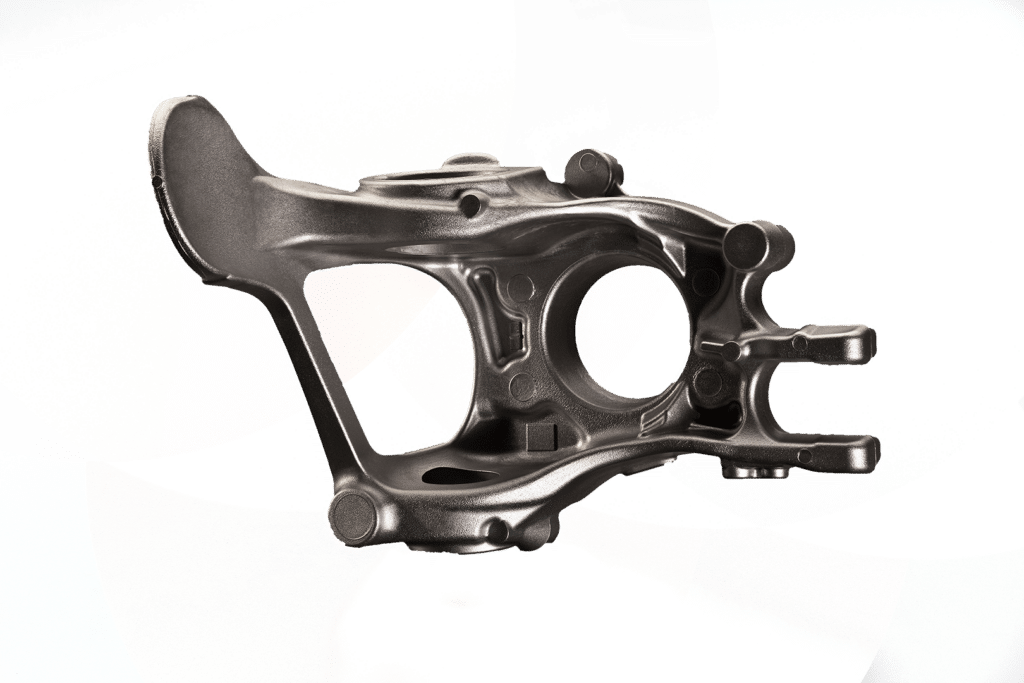

What we produce

Sample components

Express - Inquiry +49 163 227 0 229

– Do you have technical data, details and specific information about the component? Ideally, you have a CAD model or at least a technical drawing in PDF format.

– How many units do you need for express production?

– What delivery time is required? Is there flexibility in terms of delivery time, with a minimum and maximum delivery time?

– What material is the workpiece or components to be made of? Are there options for alternative materials?

– Is there interest in additional surface treatments besides CNC machining?

– Can you name a contact person who will be available for any questions during the entire production period of the express order?

– Should the express parts be delivered to one address in Germany after production? Or do several locations need to be supplied?

In emergencies, many of our customers prefer the express manufacturing processes of turning and milling. Particularly urgent express sheet metal processing is also an established option at Streametal. We owe our speed to state-of-the-art CNC machine tools, our extensive expertise and powerful infrastructure.

The advantage of express turning is that we can produce a high number of pieces quickly in emergencies without compromising quality. We also manufacture express milled parts at the same pace from a block of material we have previously cut to size.

At Streametal, almost all the necessary clamping devices and tools are available for all manufacturing processes. We also regularly receive orders for express surface finishes such as hardening, burnishing, anodising, nitriding, grinding or galvanising.

Although most of our manufacturing processes are subtractive, Streametal’s customer value is highly additive. Our express products add value at a breathtaking pace. We ensure that your project moves quickly and successfully from concept to realisation.

Streametal presents itself as a comprehensive manufacturing partner 4.0. Our CNC manufacturing components benefit not only from highly automated machinery, but also from lean, digital ordering and manufacturing processes. In this way, we also ensure the rapid implementation of urgent express orders with the utmost reliability.

Our CNC production spectrum is characterised by particularly high speed in the areas of turning, milling, edging, bending and punching. Any difficulties are solved quickly, express capacities are available at all times, set-up times are minimal and our customer service responds promptly.

Our extensive range of different machine tools, tools and multitools allows us to access resources at any time. In addition, we keep various materials in stock for production, and if this should not be the case, we have short and reliable connections to competent material suppliers.

Express turning is similar to express milling. Our many years of expertise and extensive experience enable us to quickly mill components and workpieces from a block of material that we have previously machined. Our high-performance CNC milling machines with 3 or 5 axes offer up to 4 degrees of freedom for precise 3D milling.

Despite the subtractive nature of most of our manufacturing processes, Streametal offers additive customer value. Our express products create real added value at fair prices. Our CNC express manufacturing ensures that your project moves quickly and successfully from idea to implementation. Compromise solutions are not an option at Streametal.