Sheet metal processing with the highest precision

Laser cutting

1.000+

2.000+

Maschinen

0,12%

Audit-approved suppliers

Economic prices

Fast delivery

Wide range of materials

Modern manufacturing with customised delivery.

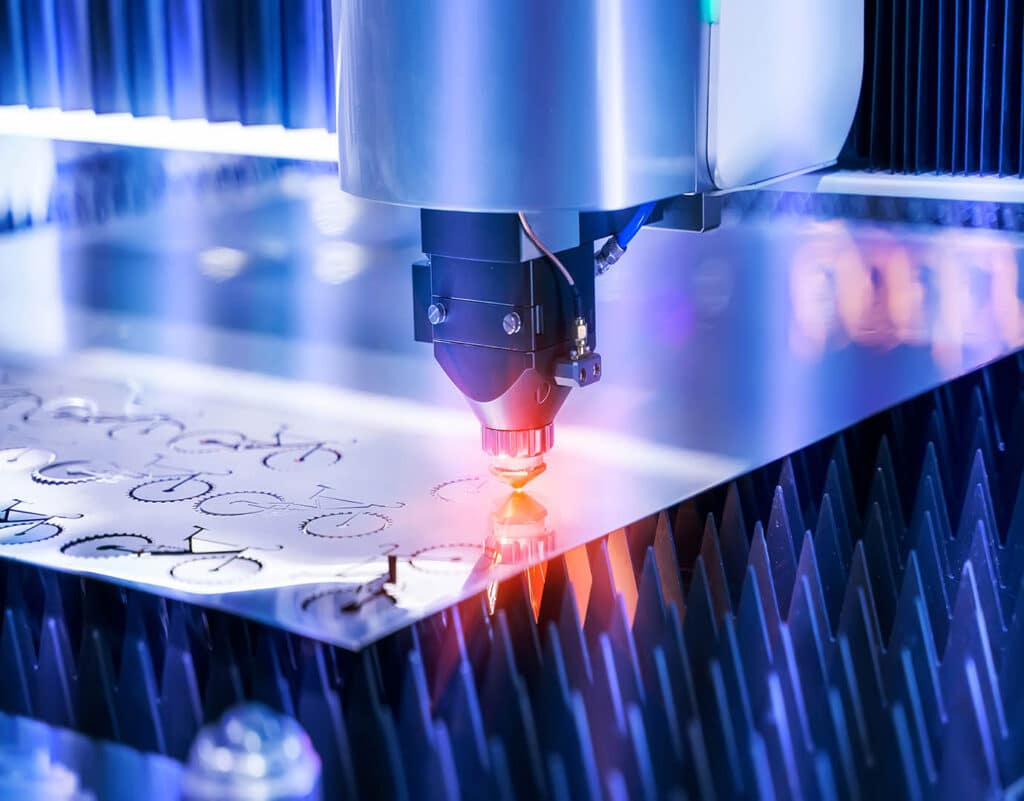

Precise mastery of highly complex tasks through laser cutting.

Laser cutting

Technical data

| travels | X-axis: up to 6,000 mm Y-axis: up to 3,200 mm |

| Material thickness | up to 50 mm |

| Tolerances | up to +/- 0,1 mm |

| Batch sizes | from 1 piece |

| Best file formats | STEP, PDF, DXF |

Our materials

Available materials

Aluminium

Bronze

Stainless steel

Steel

Spring steel

Brass

Nickel silver

other materials on request

Supported formats

File format

Short explanation

How does laser cutting work?

In laser cutting, a workpiece is cut by the continuous or pulsed laser beam, which removes the material. Depending on the material thickness and product requirements, different processes such as laser fusion cutting, laser flame cutting or laser sublimation cutting are used.

In laser fusion cutting, the material to be removed is continuously melted at the cut edges and blown out with a gas. In laser flame cutting, the material is burnt directly in the cut edges. In laser sublimation cutting, the material is directly vaporised.

Streametal mainly uses CO2 lasers. Only for temperature-sensitive materials such as copper or aluminium do we use solid-state lasers that work with a neodymium-doped YAG crystal (Nd:YAG) in the near-infrared range.

Laser cutting is characterised by precise and sharp material removal and is suitable for both small and large quantities.

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Surface processing

We maximise the potential of your components

- Sandblasting

- Painting

- Anodising

- Powder coating

- Electroless nickel plating

- Galvanising

- Passivating

- Chromating

Our manufacturing processes

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

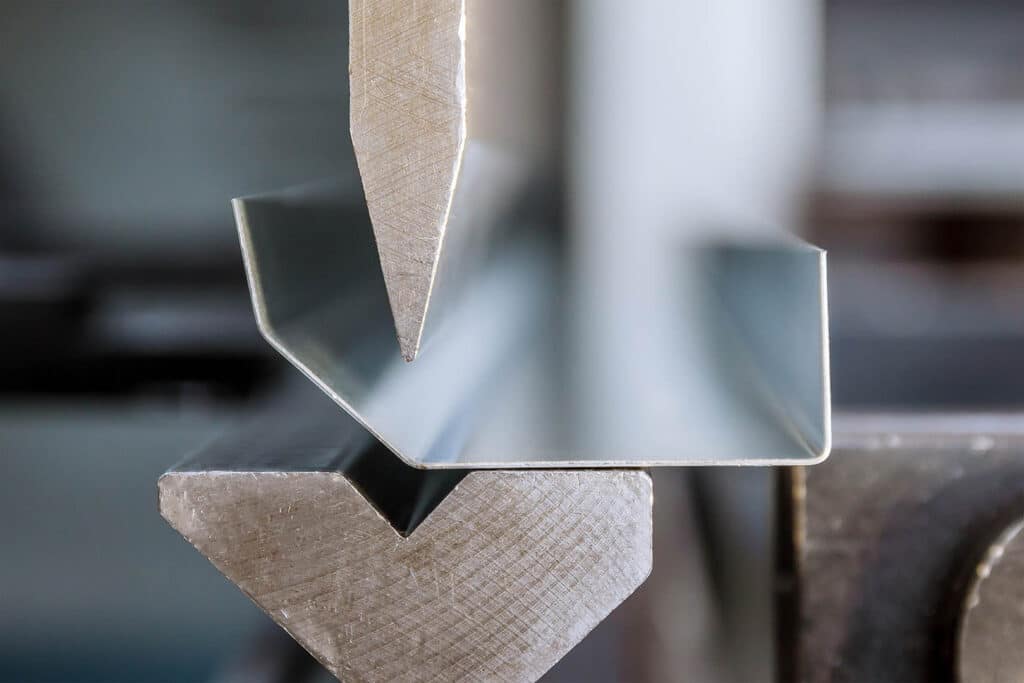

Bending

Punching

Laser cutting

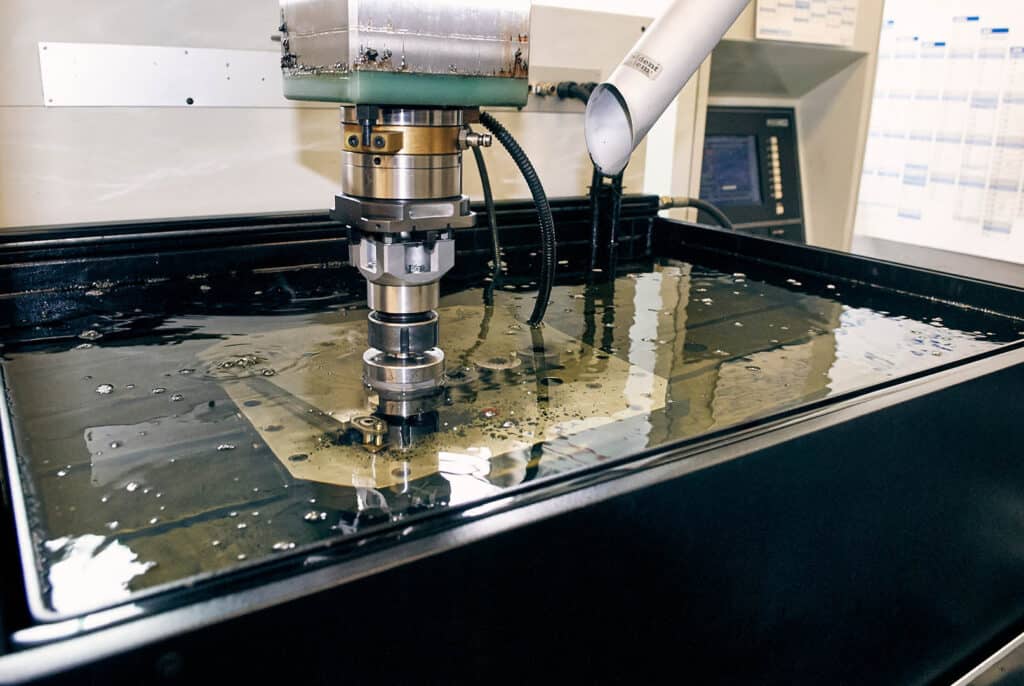

Water jet cutting

Eroding

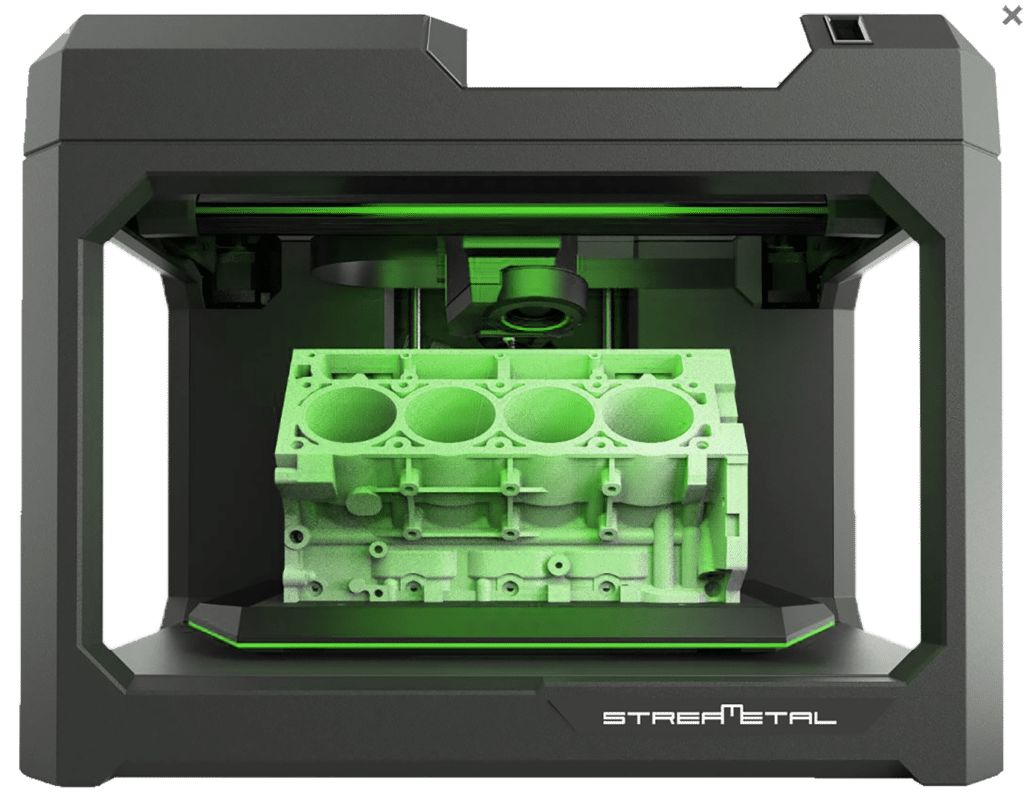

3D printing

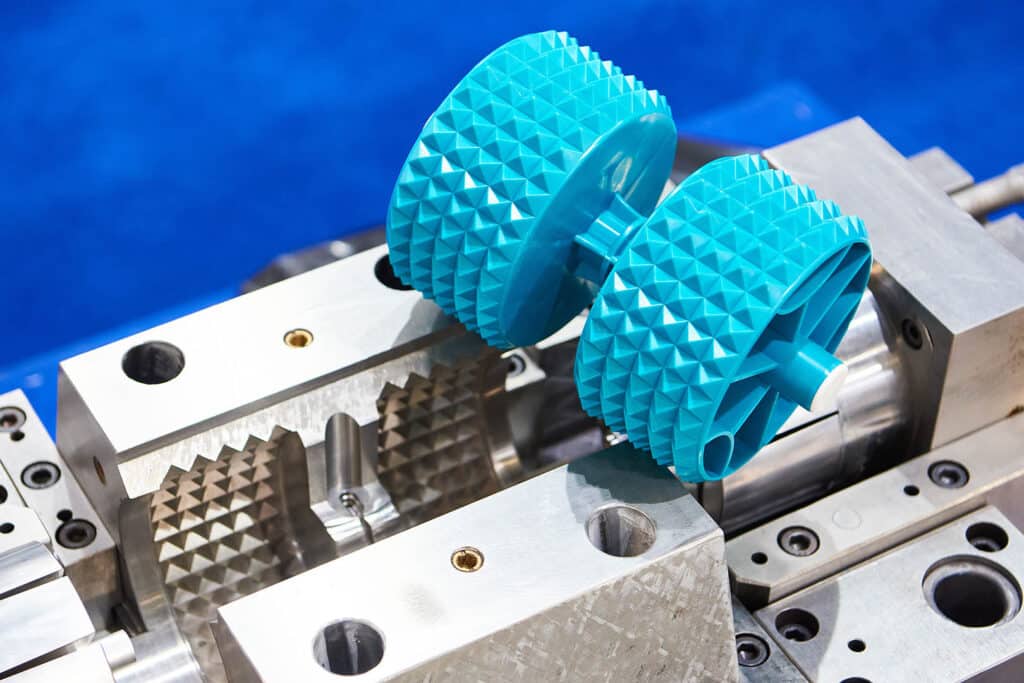

Injection moulding

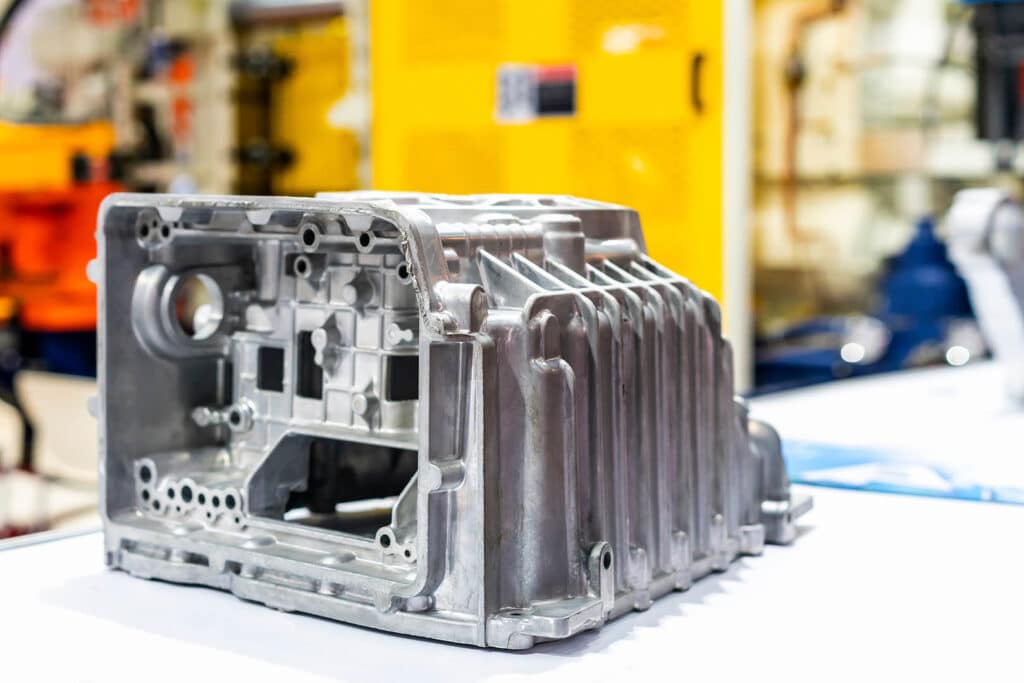

Die casting

Surface treatment