Sheet metal working in large quantities

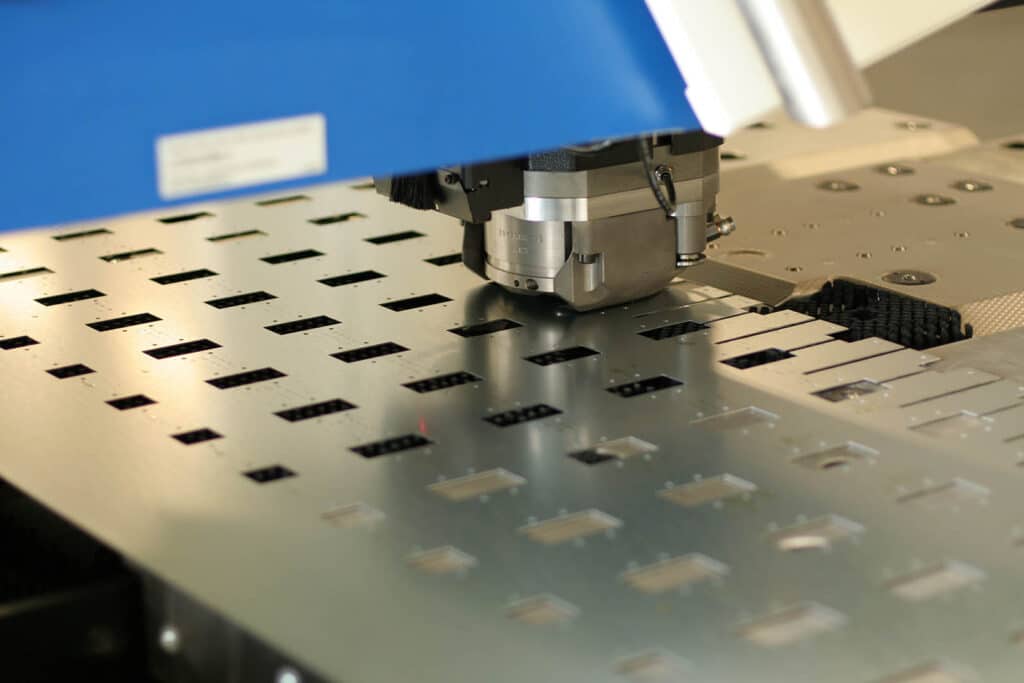

Punching

1.000+

2.000+

Maschinen

0,12%

Audit-approved suppliers

Economic prices

Fast delivery

Wide range of materials

Modern manufacturing with on-demand delivery

Sheet metal punching and nibbling to your specifications.

Even in the era of laser cutting, modern lifting dies remain an outstanding choice for exceptional product quality. The proven manufacturing techniques of stamping and nibbling enable high production speeds at attractive costs. At Streametal, sheet metal stamping and nibbling manufacturing takes care to ensure that the surface of the sheet metal ranges from virtually scratch-free to completely scratch-free.

To meet our customers’ needs quickly and flexibly, we have hundreds of punching tools and multitools in various shapes and sizes available at all times. The most commonly used shapes are round, square and rectangular.

Punching

Technical data

| Material thickness | up to 8mm |

| Diameter | max. 30 mm |

| Geometries | round, square, angular |

| Ideal batch size | from 2.000 pieces |

Our materials

Available materials

Aluminium

Bronze

Stainless steel

Steel

Spring steel

Copper

Brass

Spring steel

Supported formats

File format

Short explanation

How does punching actually work?

Unlike laser cutting, punching does not require material melting. Punching and nibbling belong to the mechanical cold-forming processes in which the materials are not exposed to heat and thus thermal stresses can be avoided.

At Streametal, we only use high-quality punching tools and multitools. Our lifting punches are equipped with automatic change magazines that can exchange tools fully automatically. The flexible, flying punching head can rotate the tools in any angular position. By using active dies and retractable clamping claws, we achieve the highest precision while protecting the material.

Our punching and bending machines are versatile. They can not only punch, but also nibble, bend sheet metal parts and insert threads at the same time. At Streametal, we even use combined punching-laser systems that combine the methods of punching and laser cutting in one operation.

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Surface processing

We maximise the potential of your components

- Sandblasting

- Painting

- Anodising

- Powder coating

- Electroless nickel plating

- Galvanising

- Passivating

- Chromating

Our manufacturing processes

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

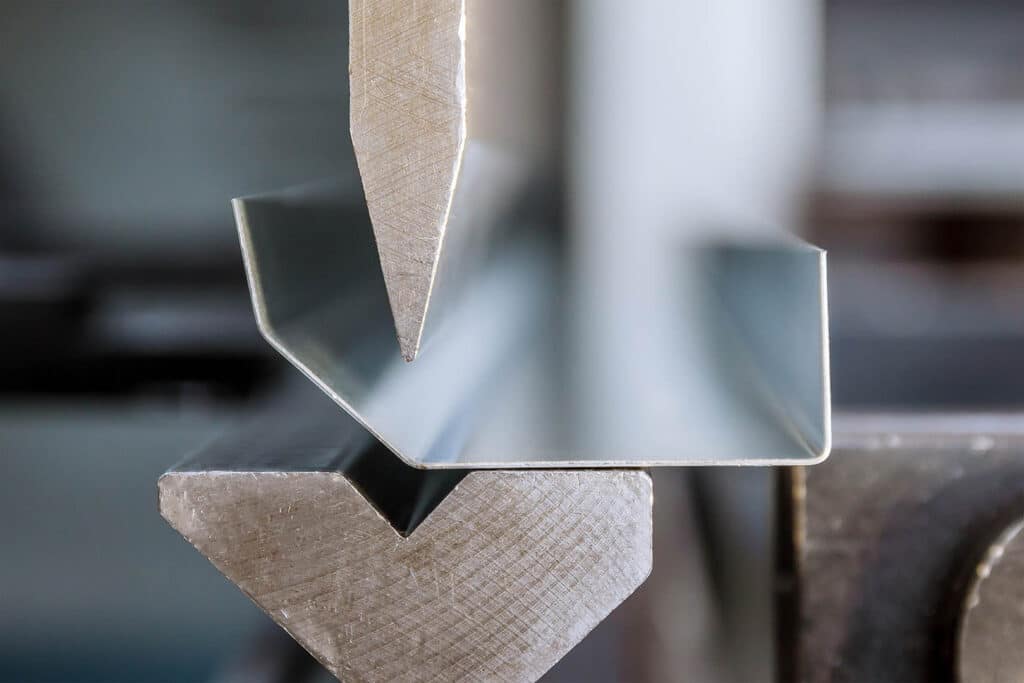

Bending

Punching

Laser cutting

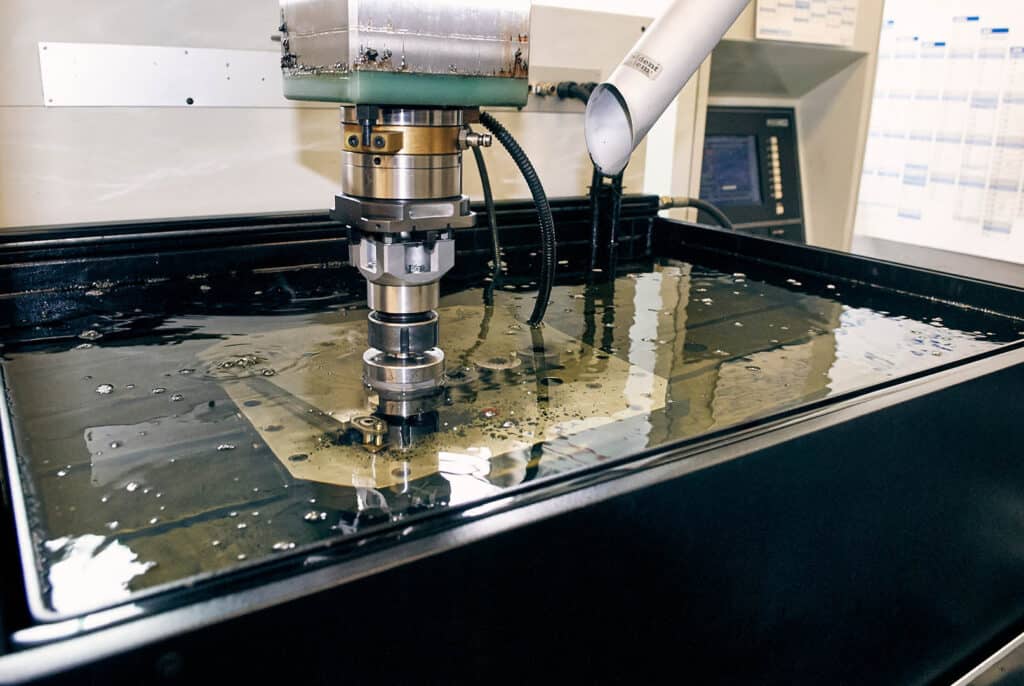

Water jet cutting

Eroding

3D printing

Injection moulding

Die casting

Surface treatment