We process metal according to your specifications.

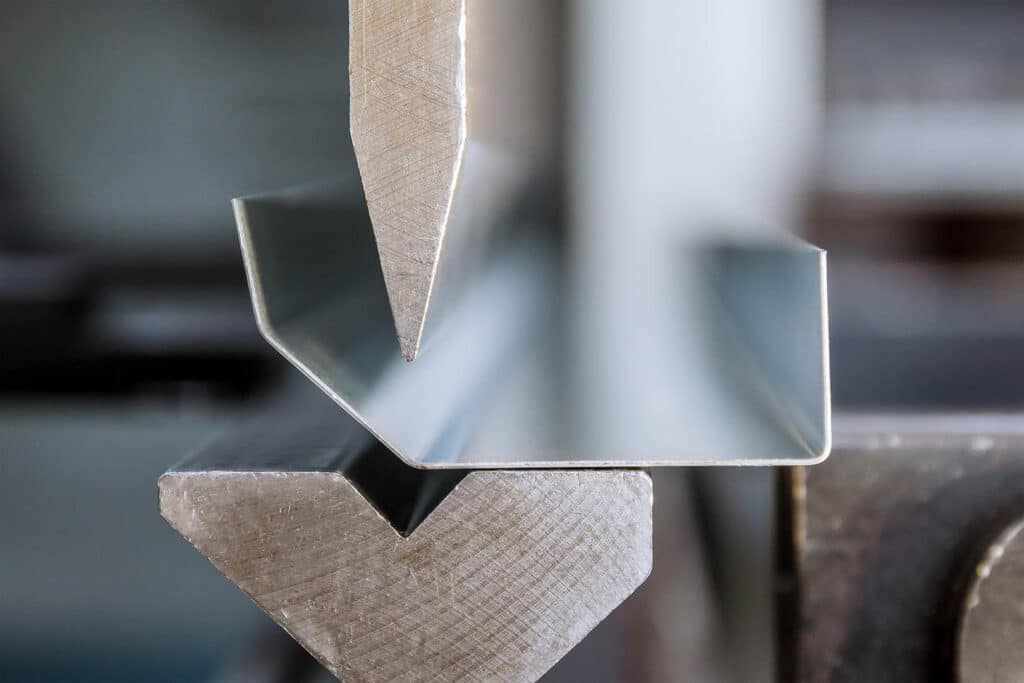

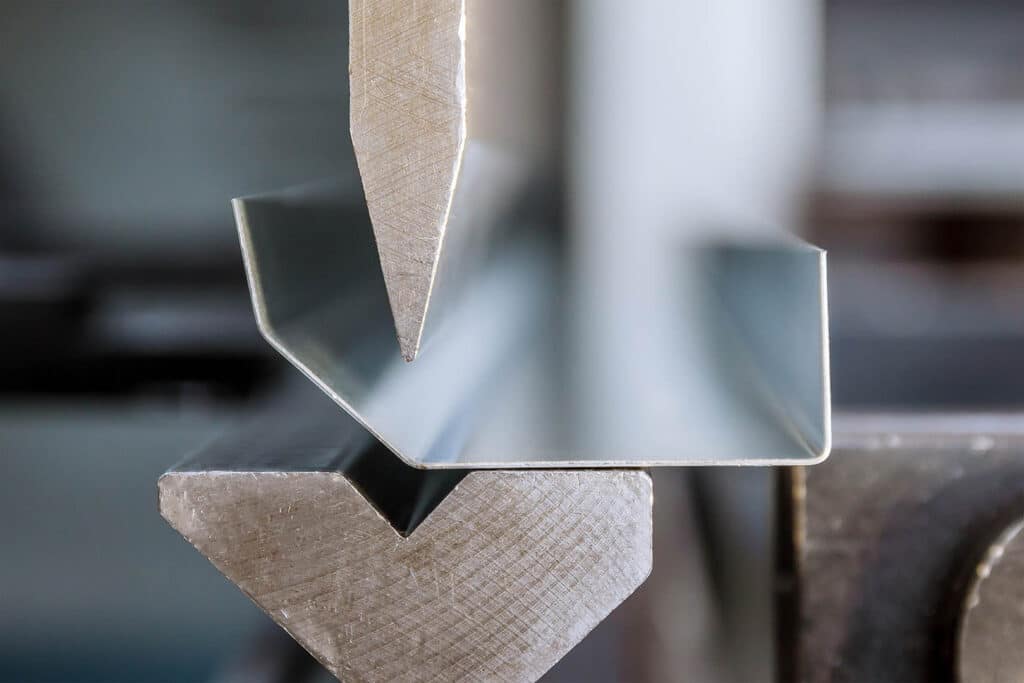

Bending

We offer you the possibility to order sheet metal parts online for bending and edging processes. With a wide range of materials and precise sheet metal processing. You can simply upload your CAD file and receive a quote within 48 hours.

1.000+

Customers

2.000+

Maschinen

0,12%

Complaint rate

Audit-approved suppliers

Worldwide network with over 500 audited suppliers

Economic prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

Reduce your delivery times by up to 50% with Streametal

Wide range of materials

Over 600 materials available: All common plastics and metals are available

We are your contact for all types of bending processes.

We shape your sheets and tubes by precise bending.

Streametal has a wide range of bending processes such as die bending, swivel bending and roll bending. We are able to precisely bend all common metals and alloys. We specialise in the production of components with complex shapes, tight radii and large and small leg lengths. Thanks to our large selection of manufacturers, we can also bring sheet metal in unusual sizes or with special thicknesses into the right shape.

Bending

Technical data

| Material thickness | <20mm |

| Available lengths | X-axis up to 3,100 mm Y-axis up to 2,600 mm |

| Ideal batch sizes | 1 - 50.000 pieces |

Our materials

Available materials

Aluminium

Bronze

Stainless steel

Steel

Inconel

Plastics

Copper

Brass

Titanium

other materials on request

Supported formats

File format

Short explanation

How does bending actually work?

The bending and folding of sheet metal is a non-cutting forming process in which the workpiece is brought into a certain shape by the application of mechanical force. The angle of the bend can be as large as desired. A distinction is made between the bending of sheet metal and the round bending of bars and tubes.

There are essentially three bending processes, including die bending, in which the material to be formed is pressed by a punch into a die with the final shape.

In swivel bending, the sheet is fixed in a stop system while an upper beam presses the sheet against a specially shaped lower beam. An angle is then formed into the sheet with the help of a bending cheek.

In roll bending, the sheet is formed by rotating rollers. In the process, the material is passed between the rollers and formed into the desired shape by the deformation. Depending on the design of the rollers, patterns or embossing can also be transferred to the sheet.

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Surface processing

We maximise the potential of your components

We not only offer the production of components, but also take care of their finishing, appearance, protection against wear and corrosion. All these aspects are part of our core business and we therefore bring out the best in your components.

- Sandblasting

- Painting

- Anodising

- Powder coating

- Electroless nickel plating

- Galvanising

- Passivating

- Chromating

Our manufacturing processes

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

Bending

Punching

Laser cutting

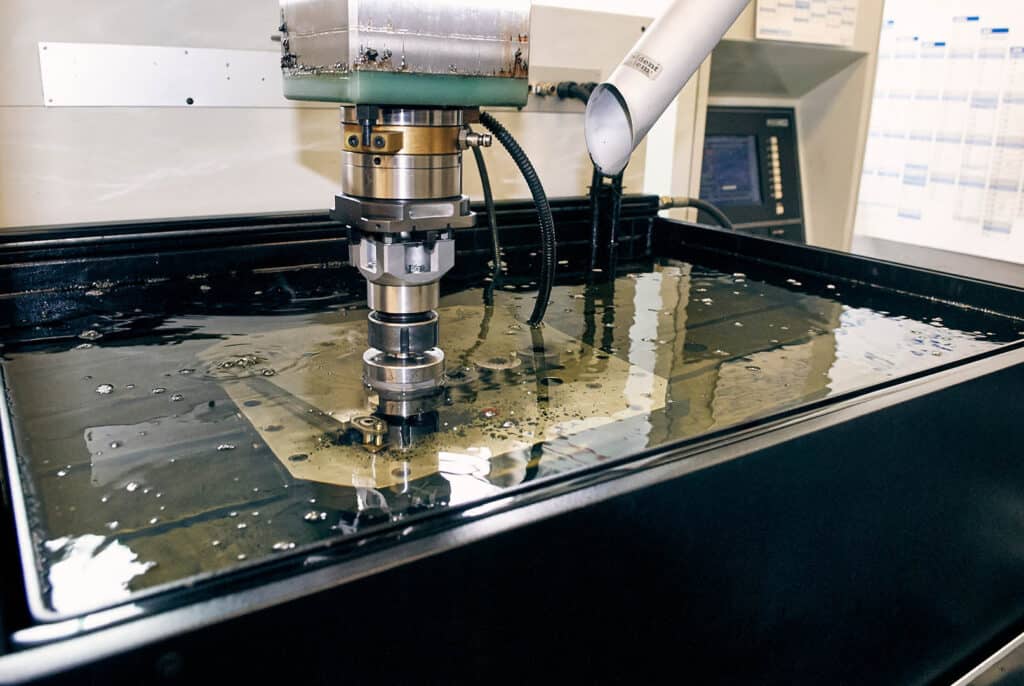

Water jet cutting

Eroding

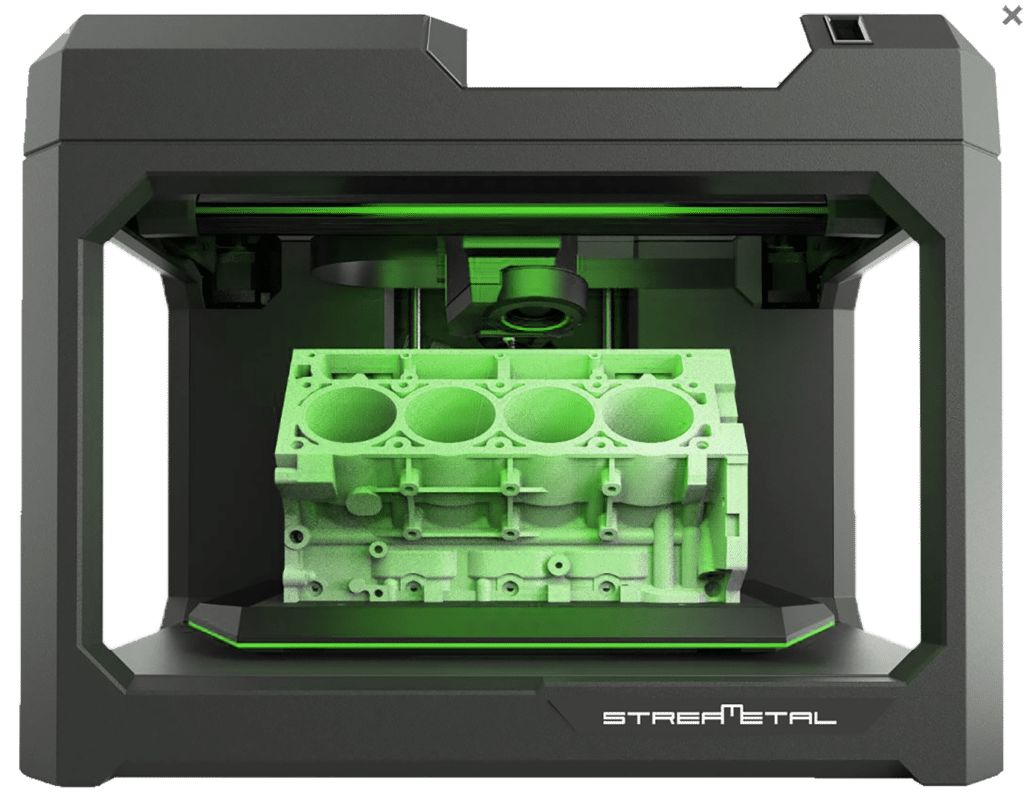

3D printing

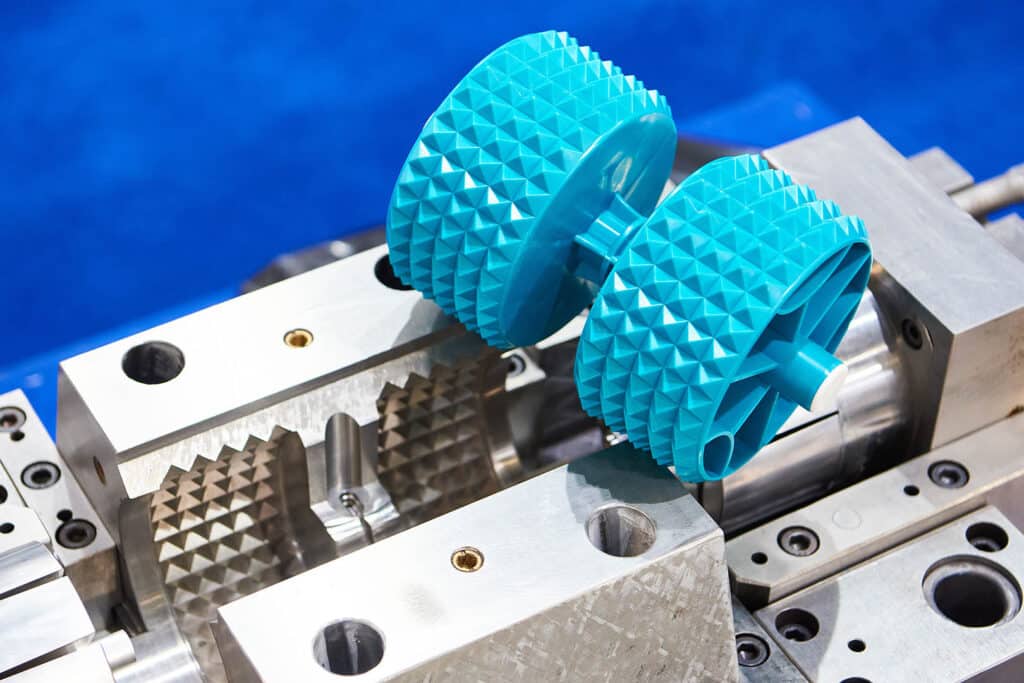

Injection moulding

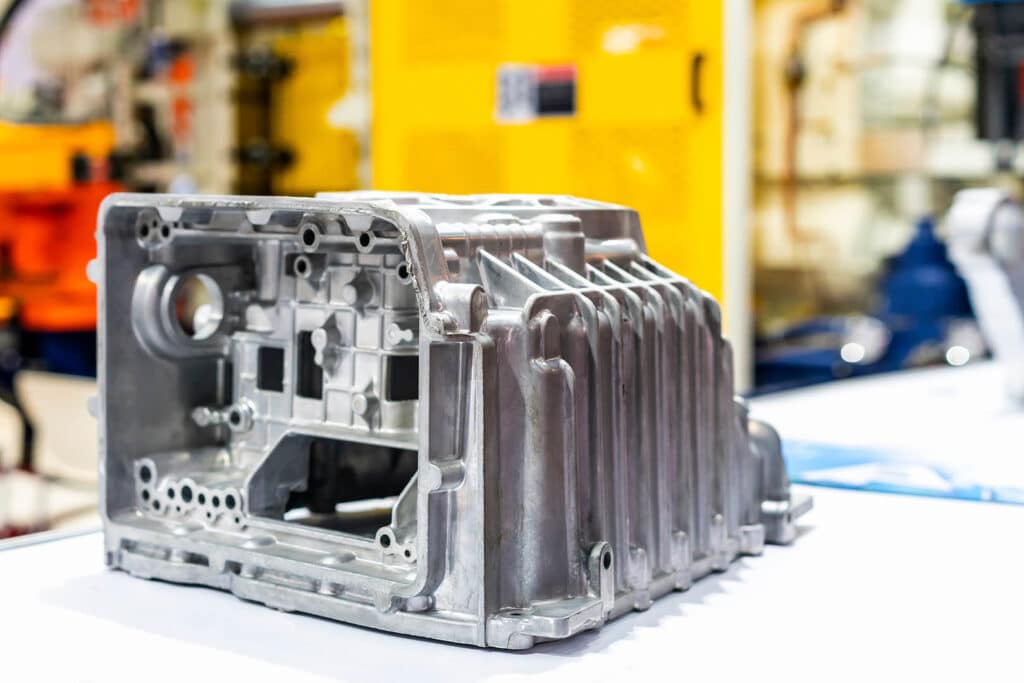

Die casting

Surface treatment

Sheet metal working

Experience you can build on

The Streametal team combines over 30 years of experience in the manufacture of precision components

250+

Finished

2000+

Machines

125.000

Individual parts

4

Countries

Our manufacturing processes

Your components in 3 steps

1

.......................

Submit an enquiry

Simply upload your production drawing and specify the order. You will receive a quotation from us within 48 hours.

2

.......................

Quality control

Our service includes finding the right manufacturer, monitoring production and carrying out quality controls – all from a single source.

3

Components received

After successful quality control, you will receive your components from us, accompanied by a detailed test certificate.

How we protect your data

Security at Streametal

Non-Disclosure Agreement (NDA)

IP protection is important to us. All partners are subject to strict non-disclosure agreements (NDA) to protect your intellectual property and keep your purchasing conditions confidential.

Secure data transmission

Your data is transmitted end-to-end encrypted to our servers in Germany. You alone decide whether data remains on our servers after production.

Anonymised production drawings

We remove any information about you or your company on all documents before we share them with our partners for production.