We produce precise components using machining production processes

CNC turning

1.000+

2.000+

Maschinen

0,12%

Audit-approved suppliers

Economic prices

Fast delivery

Wide range of materials

Short explanation

What is CNC turning and how does it work?

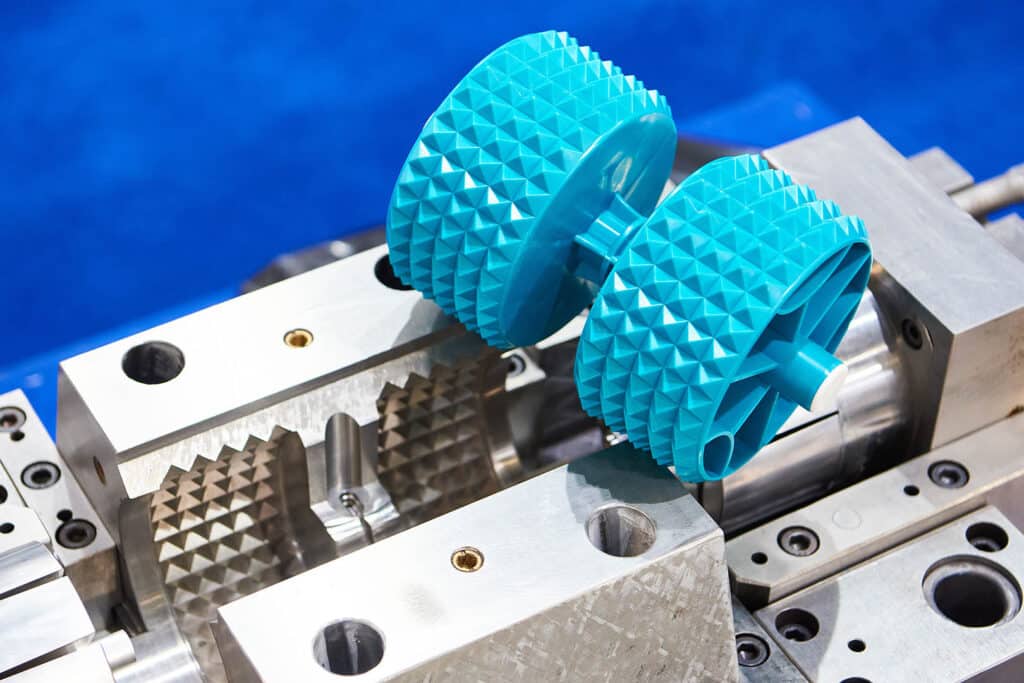

In the turning manufacturing process, the workpiece made of machinable material such as metal or plastic rotates at high speed. A turning tool attached to the tool slide moves against the bar stock workpiece in a feed motion and removes material. Similar to milling, material is subtracted to bring the workpiece into the desired shape.

In advanced machining centres, powered tools can be used to combine different turning and milling techniques. This enables the production of features such as spanner flats, threads or hexagonal edges directly on the machine.

CNC turning

Technical data

| Diameter | 1 mm - 5,300 mm |

| length | 0.5 mm - 20,000 mm |

| Tolerances | up to +/- 0.05 mm |

| Surface roughness | up to Ra 0.8 / Rz3.2 |

| Materials | Over 600 materials |

| Lot sizes | from 1 piece |

Our materials

Available materials

Aluminum

Bronze

Cast iron

Stainless steel

Steel

Hard fabric

Inconel

Ceramics

Plastics

Copper

Brass

Titanium

other materials on request

Supported formats

File format

Turned parts with precision

CNC turning with on-demand delivery

Streametal enables uncomplicated procurement processes and fast delivery of components of the highest quality.

We process all machinable materials, including metals and plastics. When it comes to CNC turning, the materials such as aluminium, steel, stainless steel or plastics are almost limitless. Our modern machines and processes enable us to produce prototypes, individual parts, small and large series precisely on-demand and deliver them on time.

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Surface processing

We maximise the potential of your components

- Sandblasting

- Painting

- Anodising

- Powder coating

- Electroless nickel plating

- Galvanising

- Passivating

- Chromating

Our manufacturing processes

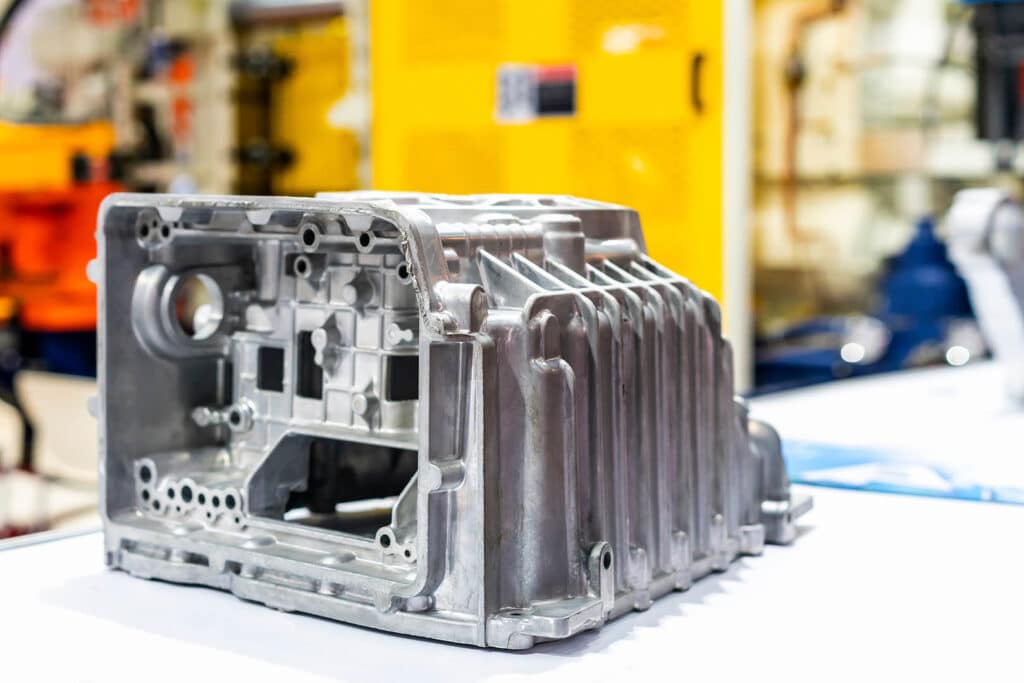

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

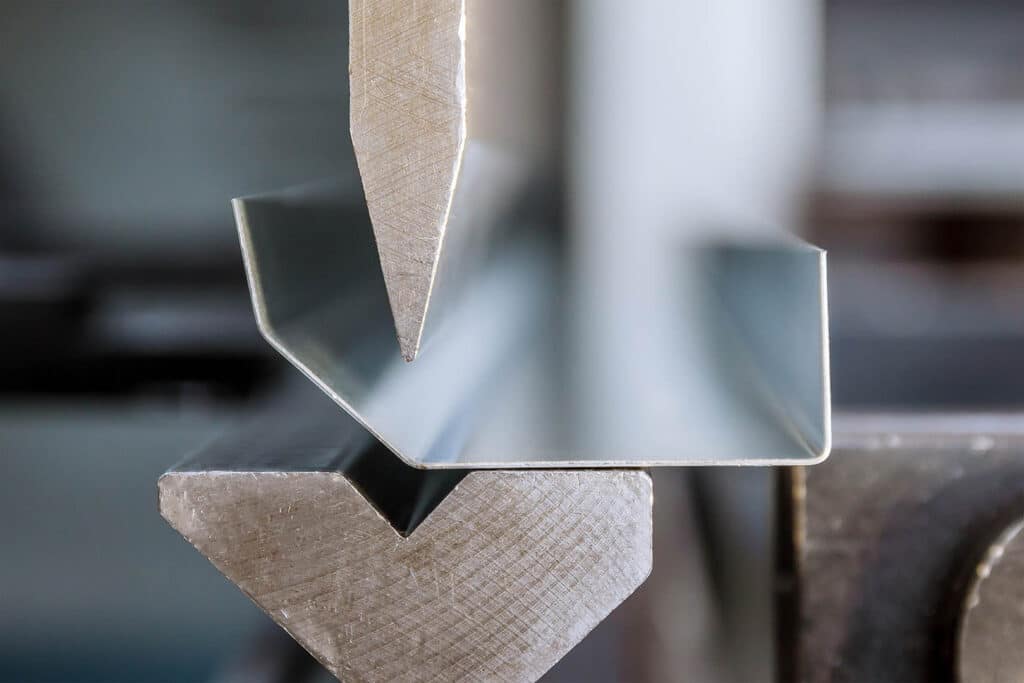

Bending

Punching

Laser cutting

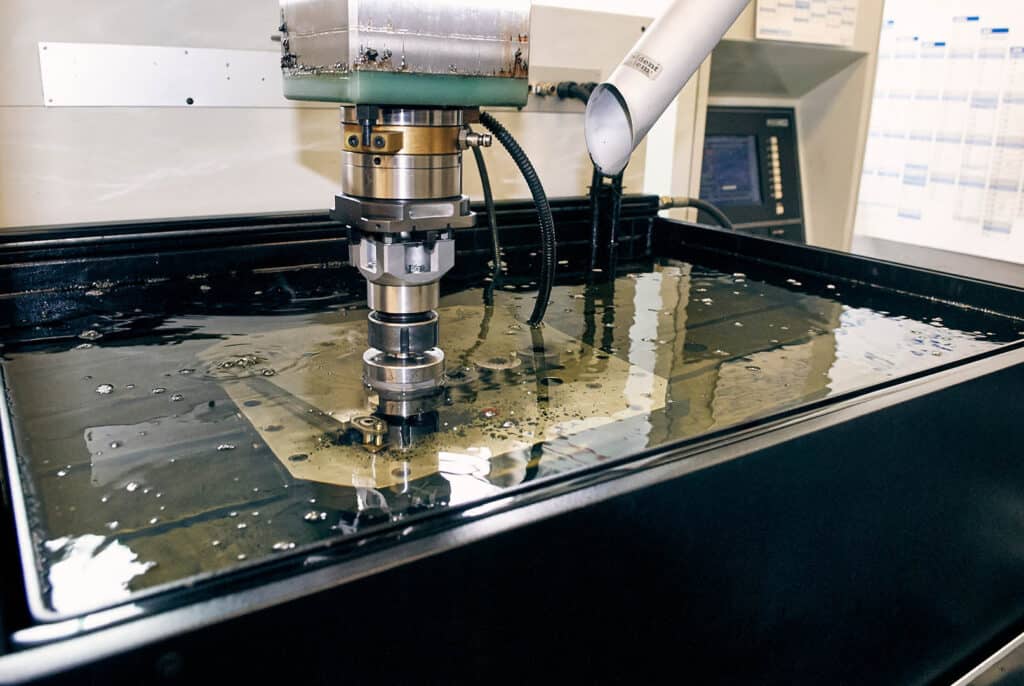

Water jet cutting

Eroding

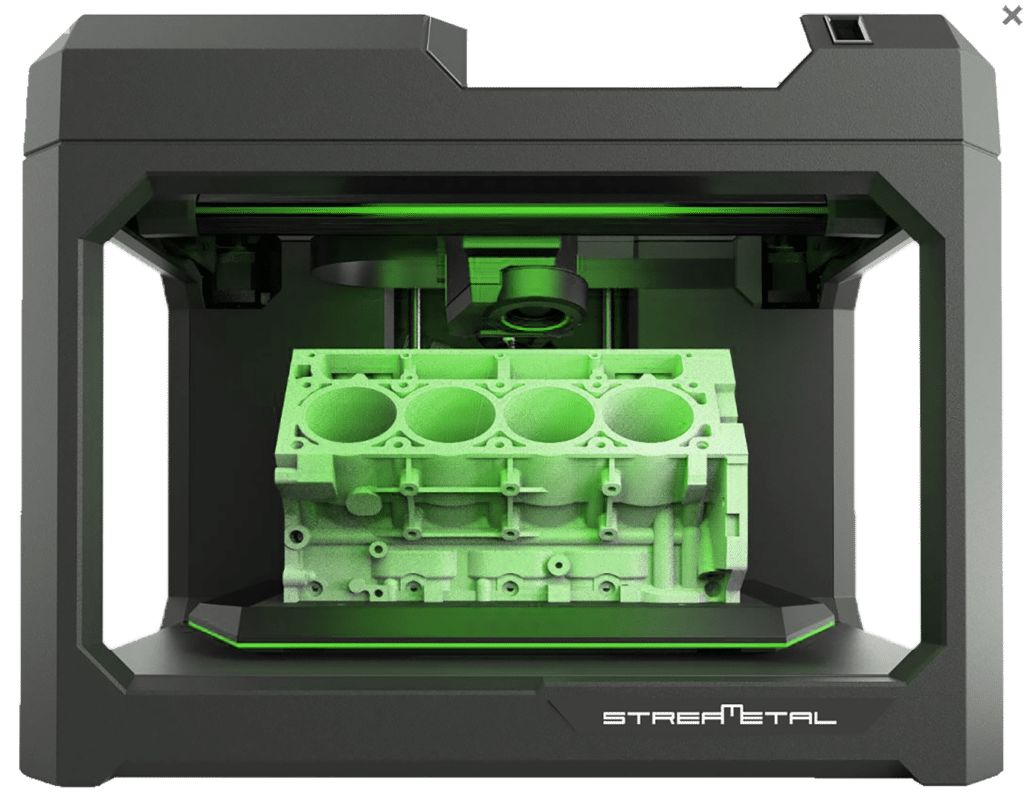

3D printing

Injection moulding

Die casting

Surface treatment