Rapid prototyping and series production

3D printing

Your partner for rapid prototyping and series production in the field of 3D printing. Modern manufacturing with SLS, SLA, FDM and Polyjet processes. Attractive prices, wide range of materials and fast delivery. Upload CAD files and receive a quote within 48 hours.

1.000+

Customers

2.000+

Maschinen

0,12%

Complaint rate

Audit-approved suppliers

Worldwide network with over 500 audited suppliers

Economic prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

Reduce your delivery times by up to 50% with Streametal

Wide range of materials

Over 600 materials available: All common plastics and metals are available

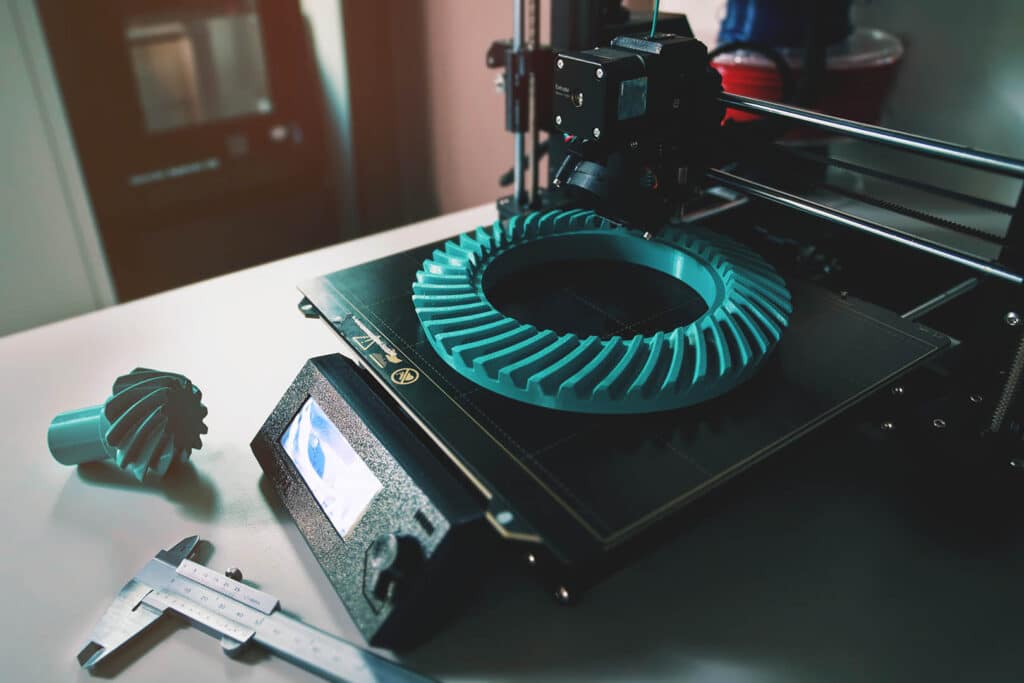

Additive manufacturing in 3D printing

Using 3D printing for rapid prototyping and small batch production

Are you looking for a partner who can produce highly accurate and reproducible prototypes and small batches using 3D printing? Our service at Streametal focuses on additive manufacturing of functional prototypes and small series with rapid availability. We are happy to support you in the areas of rapid prototyping, rapid tooling and small series production to manufacture your desired components.

3D Printing

Technical data

| Material thickness | 0.1 mm - 10 mm |

| Length | 10 mm - 2.000 mm |

| Tolerances | up to +/- 0.01 mm up to +/- 0.3 mm |

| Surface finish | 3.2 Ra µm |

| Batch sizes | >1 |

Our materials

Available materials

Aluminium

Bronze

Copper

Stainless steel

Steel

Titanium

Inconel

PLA

ABS

Synthetic resins

Nylon

PETG

TPU, TPU Ultrasint

PA11, PA12, PA12 GF/GBellen.

Supported formats

File format

Our processes

3D printing process

- Polyjet (MJM)

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Fused Deposition Modelling (FDM)

- Multi Jet Fusion (MJF)

- Stereolithography SLA

Briefly explained

How 3D printing works

The term “3D printing” covers various additive manufacturing techniques in which material is applied step by step to create a three-dimensional workpiece. 3D printing is mainly used for rapid prototyping, rapid tooling and small batch manufacturing. Here are the key manufacturing methods in 3D printing at a glance.

3D printing solutions for functional prototypes and tools.

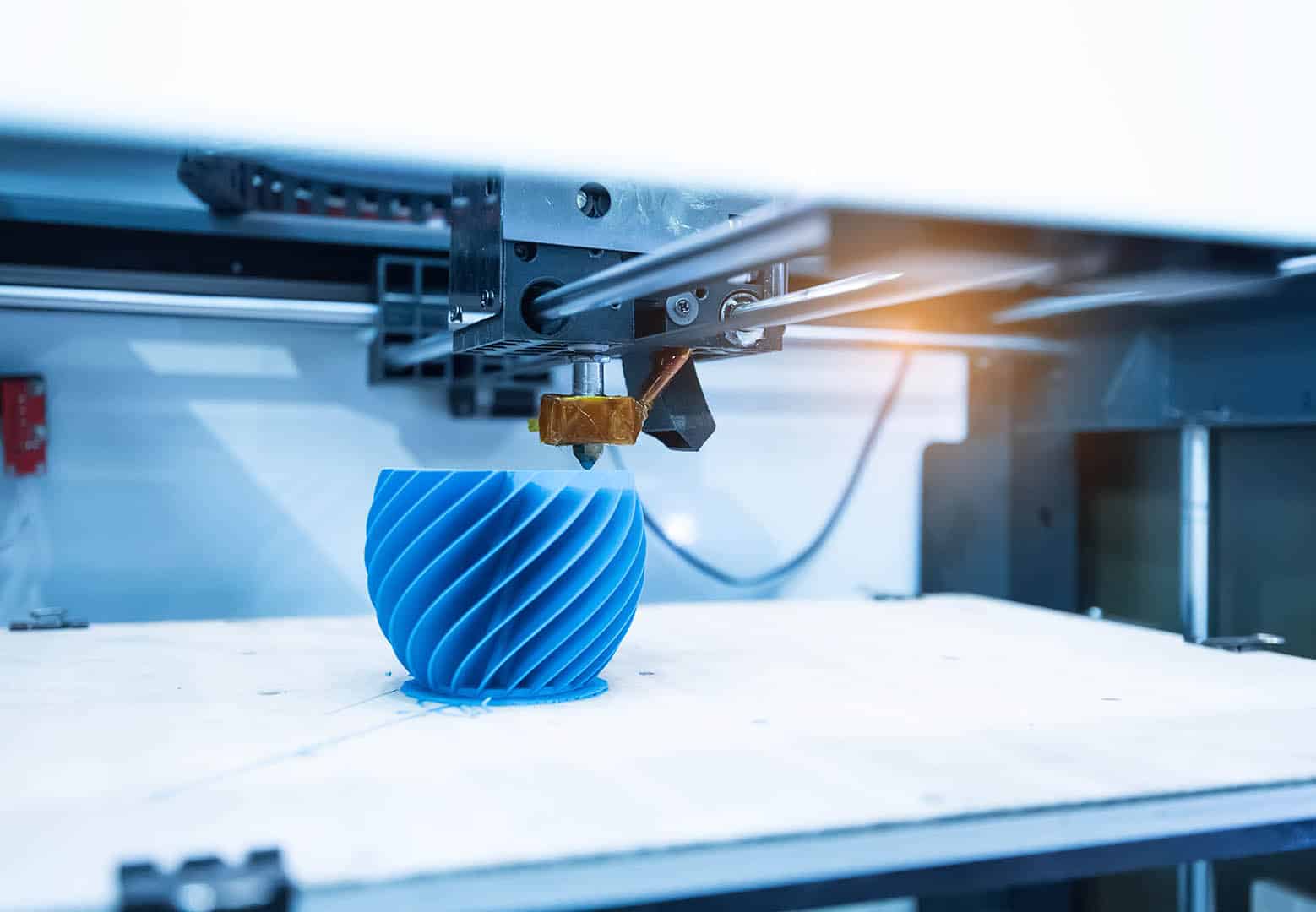

Fused Deposition Modelling (FDM)

In the FDM 3D printing process, a plastic wire, also known as a filament, is melted in the hot end of the printer and deposited layer by layer onto the print bed. It is suitable for materials that can be liquefied or deformed under heat. Typical materials are thermoplastics such as ABS, PLA, PVA, HIPS, PET, nylon as well as filaments based on metals, stone, wood and other materials. After application, the material hardens by cooling.

Unification of materials and colour design

Polyjet process (Multijet Modelling MJM)

In the Polyjet process, very fine droplets of a photopolymer are applied to a platform through a print head and immediately cured using UV light.

Polyjet enables the processing of ultra-thin layers (up to 14 μm) and offers an exceptionally high level of detail with surfaces similar to injection moulding. Different materials can be used and even mixed in production, which enables completely new material properties.

Therefore, polyjet printing is an extremely versatile process with a wide range of applications in prototyping.

Powder-based 3D printing

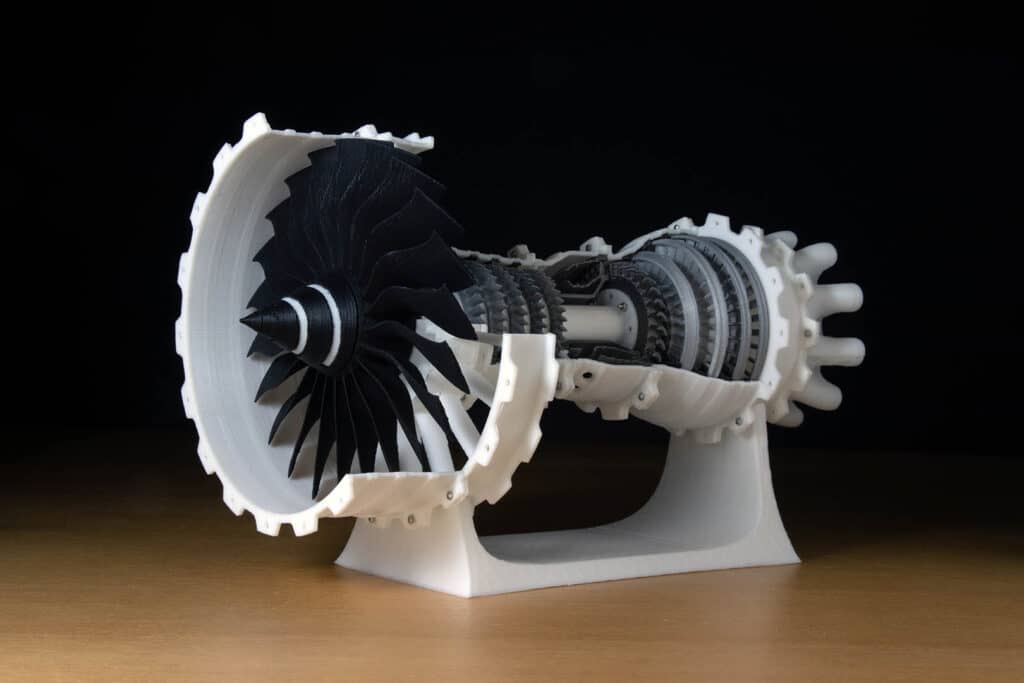

Selective Laser Sintering (SLS)

The powder bed-based 3D printing process of selective laser sintering (SLS) has particular application in the production of prototypes and finished components made of plastic and metal.

SLS 3D printers use similar working principles to SLA machines by using lasers to create components. However, in SLS printing, the component layers are formed by sintering layers of powder that are applied layer by layer, rather than resin.

The ability to process a wide range of high-precision materials makes SLS 3D printing particularly well suited to industries such as aerospace and automotive.

For components with demanding shapes and structures

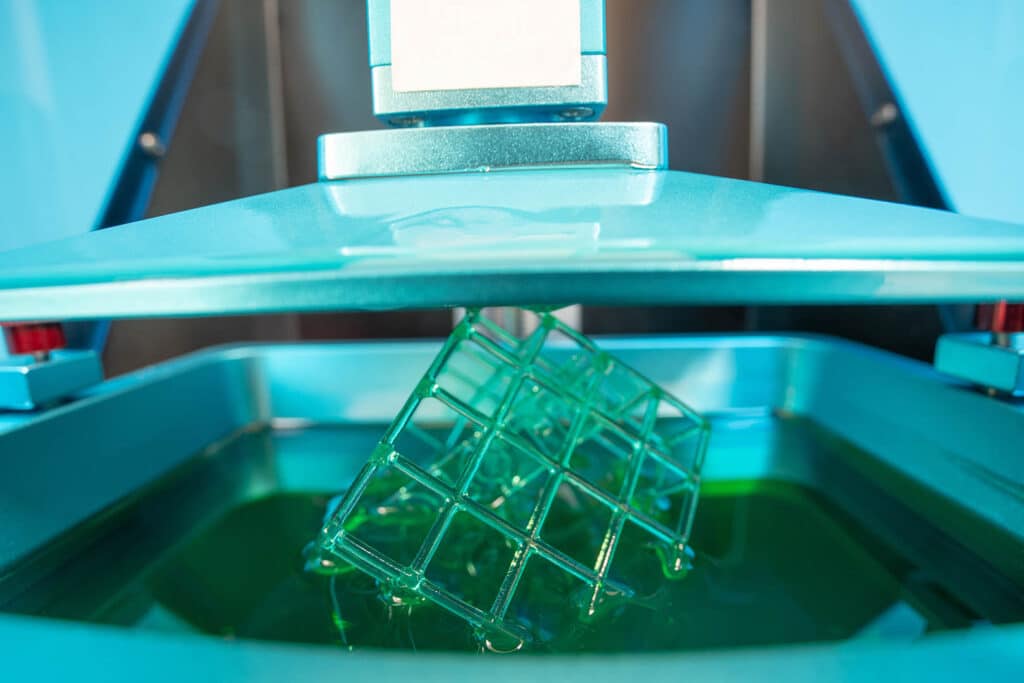

Stereolithography (SLA)

The SLA process uses a basin filled with liquid photopolymer resin, also known as resin. A UV laser cures the photosensitive material at pre-defined locations. The platform is lowered layer by layer, allowing the printing process to continue.

Since the workpiece is surrounded in a liquid during the printing process, this requires the use of support structures. These supports enable the precise production of components with extremely complex geometries. The SLA process is even suitable for use in medical technology.

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Surface processing

We maximise the potential of your components

We not only offer the production of components, but also take care of their finishing, appearance, protection against wear and corrosion. All these aspects are part of our core business and we therefore bring out the best in your components.

- Sandblasting

- Painting

- Anodising

- Powder coating

- Electroless nickel plating

- Galvanising

- Passivating

- Chromating

Experience you can build on

The Streametal team combines over 30 years of experience in the manufacture of precision components

250+

Finished

2000+

Machines

125.000

Individual parts

4

Countries

Our manufacturing processes

Your components in 3 steps

1

.......................

Submit an enquiry

Simply upload your production drawing and specify the order. You will receive a quotation from us within 48 hours.

2

.......................

Quality control

Our service includes finding the right manufacturer, monitoring production and carrying out quality controls – all from a single source.

3

Components received

After successful quality control, you will receive your components from us, accompanied by a detailed test certificate.

How we protect your data

Security at Streametal

Non-Disclosure Agreement (NDA)

IP protection is important to us. All partners are subject to strict non-disclosure agreements (NDA) to protect your intellectual property and keep your purchasing conditions confidential.

Secure data transmission

Your data is transmitted end-to-end encrypted to our servers in Germany. You alone decide whether data remains on our servers after production.

Anonymised production drawings

We remove any information about you or your company on all documents before we share them with our partners for production.