Machining with the highest precision

CNC milling

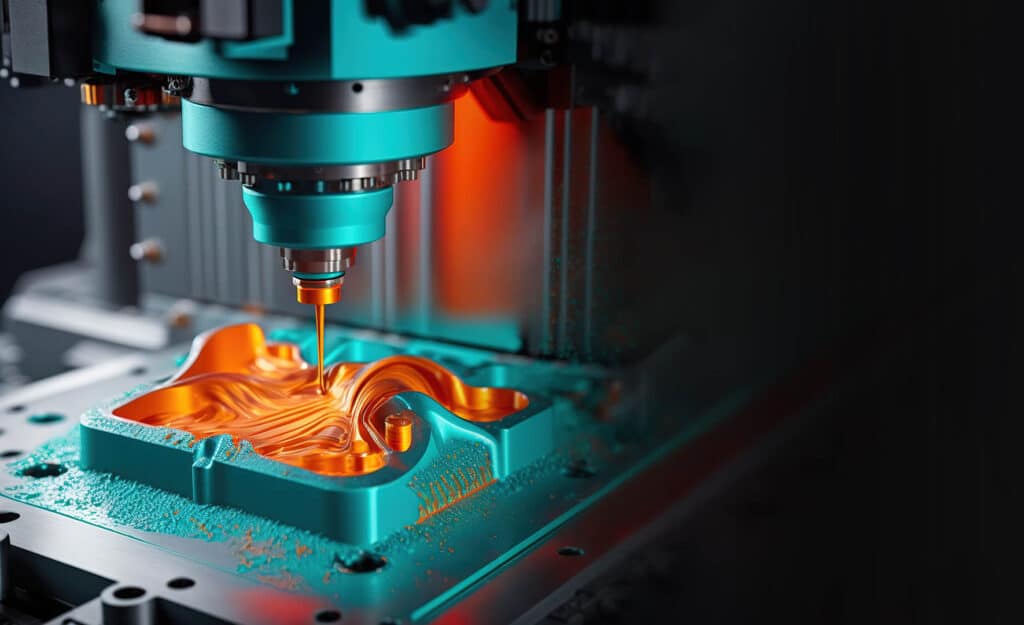

We offer you the possibility to order sheet metal parts online for bending and edging processes. With a wide range of materials and precise sheet metal machining. You can simply upload your CAD file and receive a quote within 48 hours.

1.000+

Customers

2.000+

Maschinen

0,12%

Complaint rate

Audit-approved suppliers

Worldwide network with over 500 audited suppliers

Economic prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

Reduce your delivery times by up to 50% with Streametal

Wide range of materials

Over 600 materials available: All common plastics and metals are available

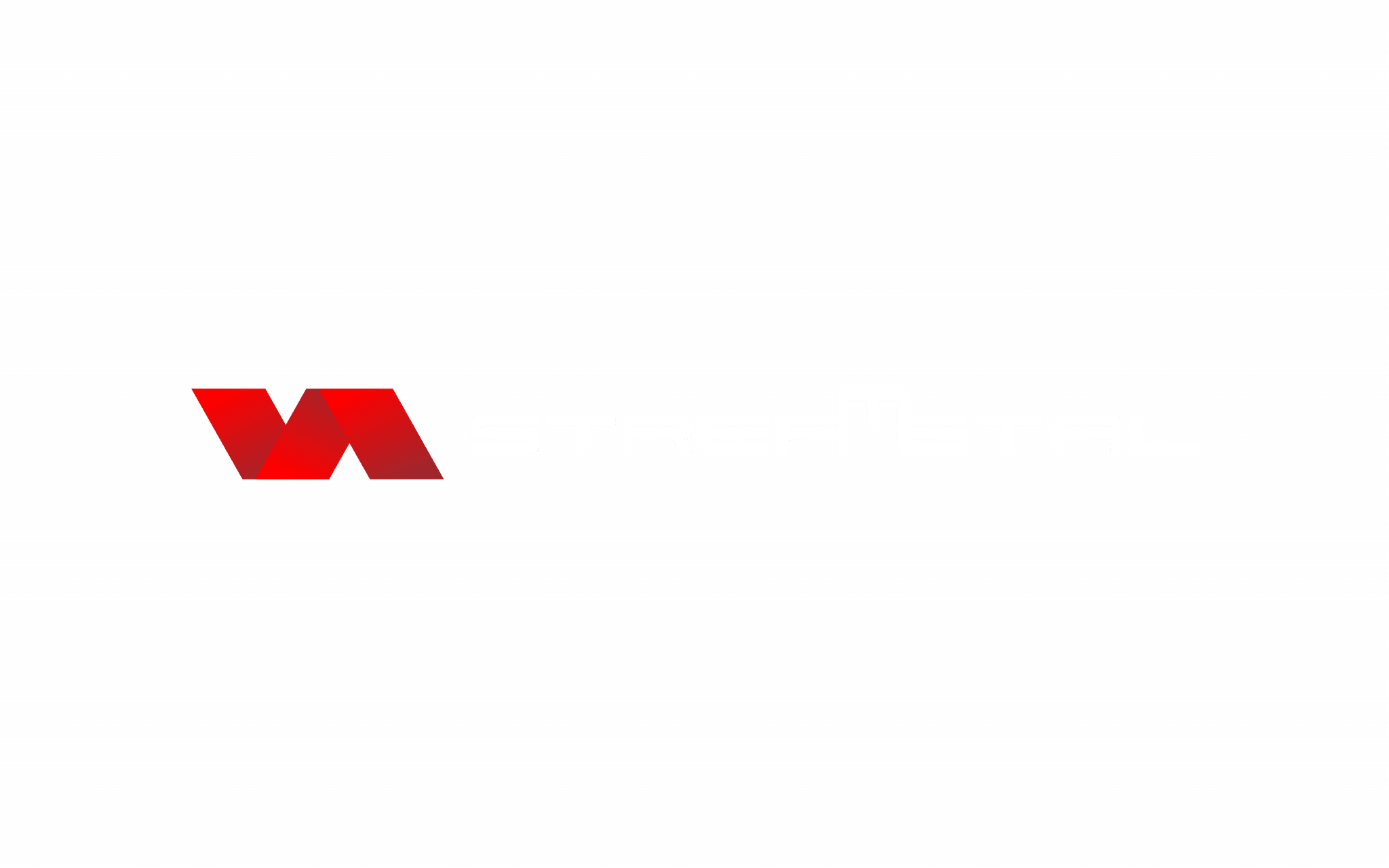

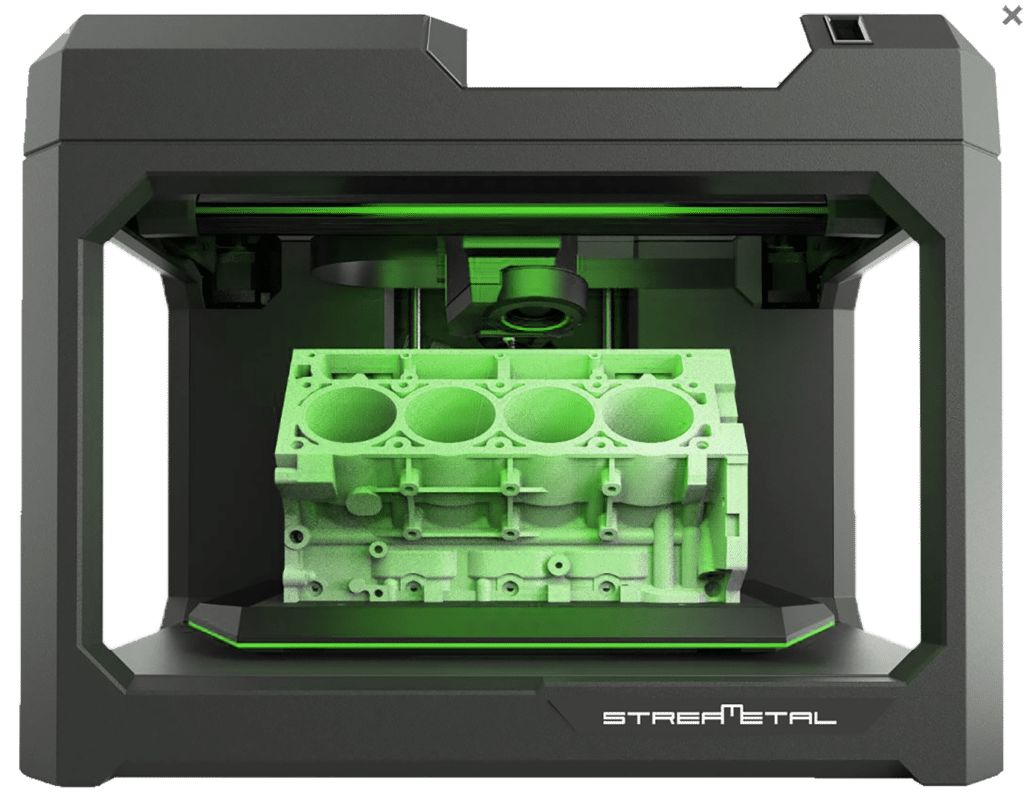

Milled parts with on-demand delivery

CNC milling of metal and plastic components

Streametal stands for uncomplicated procurement processes, punctual deliveries and the highest quality standards. Our milled parts are produced using advanced 3-axis and 5-axis milling machines.

We offer a wide range of materials and easily process aluminium, stainless steel and plastics.

Thanks to our state-of-the-art CNC milling technology, we can deliver precise parts for prototypes, spare parts or series production. You can order the parts as required and we guarantee delivery on time.

CNC milling

Technical data

| Traverse paths | X-axis: up to 10,000 mm Y-axis: up to 4,300 mm Z-axis: up to 1.250 mm |

| Tolerances from | from +/- 0.005 mm |

| Surface roughness | +/- 0.005 mm |

| Lot sizes | from 1 piece |

| Machines | Modern 3- and 5-axis milling machines |

Our materials

Available materials

Aluminium

Bronze

Stainless steel

Steel

Cast iron

Hard fabric

Inconel

Ceramics

Plastics

Copper

Brass

Titanium

Other materials on request

Supported formats

File format

Short explanation

What is CNC milling and how does it work?

Milling is a subtractive manufacturing process in which the tool plunges into the clamped material at high speed and at a specific feed rate. Compared to turning, the milling process takes place at a higher speed.

Our modern CNC milling machines use different milling heads to gradually remove material from block, plate or bar material until the workpiece has the desired shape.

The shapes and tolerances are determined by an individually created NC programme and transferred from the CNC machine to the workpiece. At Streametal, we usually use 3-axis or 5-axis milling machines to machine the prepared semi-finished products.

Streametal’s high level of manufacturing expertise not only allows us to reduce machining and set-up times, but also to increase the precision of CNC milling. Above all, it enables us to shorten throughput times when producing large quantities.

Why Streametal?

Your advantages

- Flexible and free capacity at any time

- Attractive prices for all components

- Quality control according to DIN ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

The choice is yours!

Our delivery times

- Quotation in 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

- Super express service in 72 hours

Surface processing

We maximise the potential of your components

We not only offer the production of components, but also take care of their finishing, appearance, protection against wear and corrosion. All these aspects are part of our core business and we therefore bring out the best in your components.

- Sandblasting

- Painting

- Anodising

- Powder coating

- Electroless nickel plating

- Galvanising

- Passivating

- Chromating

Our manufacturing processes

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

Bending

Punching

Laser cutting

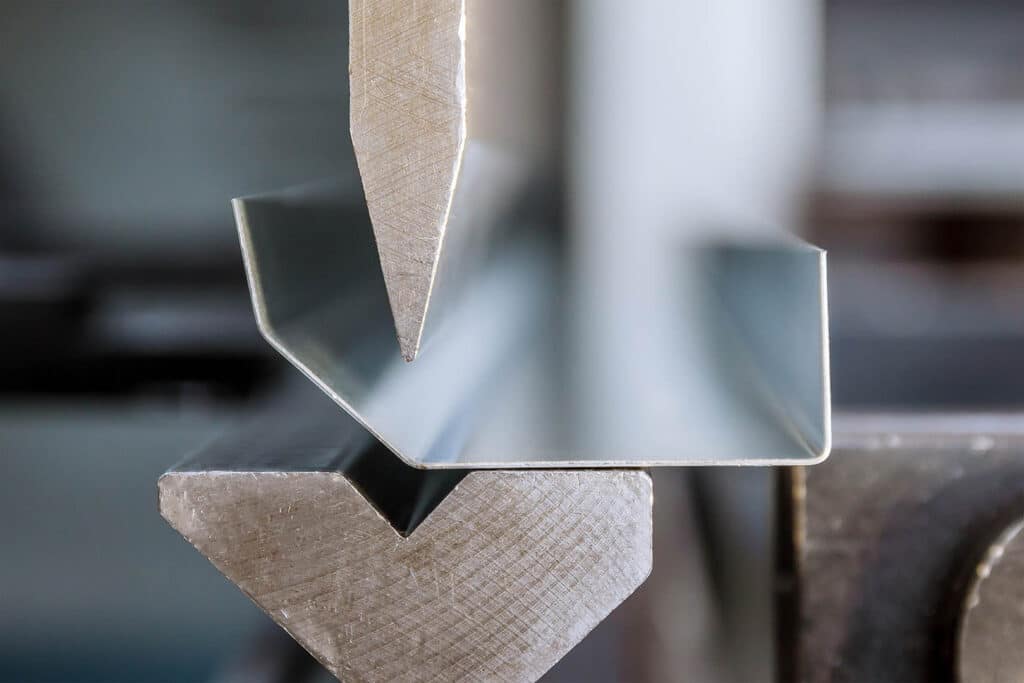

Water jet cutting

Eroding

3D printing

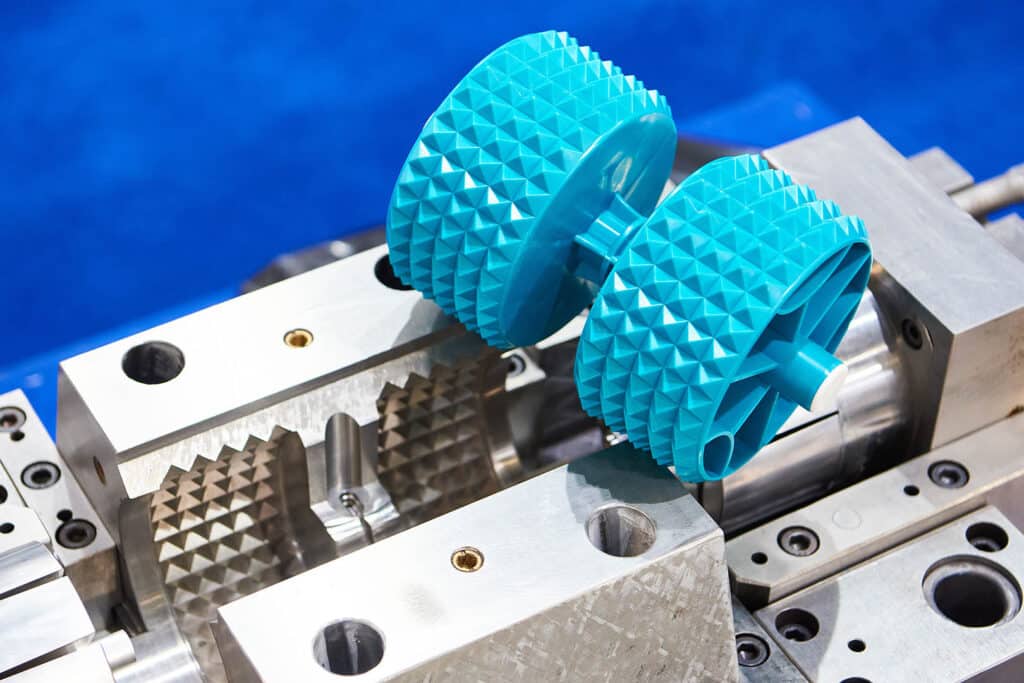

Injection moulding

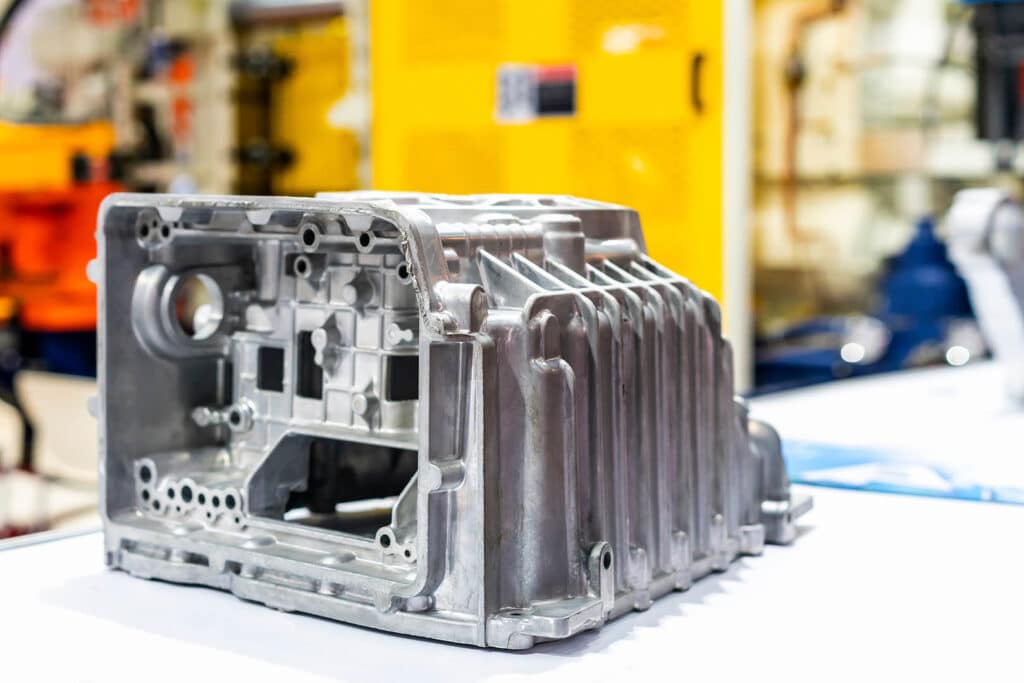

Die casting

Surface treatment

Sheet metal working

Experience you can build on

The Streametal team combines over 30 years of experience in the manufacture of precision components

250+

Finished

2000+

Machines

125.000

Individual parts

4

Countries

Unsere Fertigungsverfahren

Ihre Bauteile in 3 Schritten

1

.......................

Anfrage stellen

Laden Sie einfach Ihre Fertigungszeichnung hoch und spezifizieren Sie den Auftrag. Innerhalb von 48 Stunden erhalten Sie von uns ein Angebot.

2

.......................

Qualitätskontrolle

Unser Service umfasst die Suche nach dem geeigneten Hersteller, die Überwachung der Produktion und die Durchführung von Qualitätskontrollen – alles aus einer Hand.

3

Bauteile erhalten

Nach erfolgreicher Qualitätskontrolle erhalten Sie von uns Ihre Bauteile, begleitet von einem detaillierten Prüfnachweis.

How we protect your data

Security at Streametal

Non-Disclosure Agreement (NDA)

IP protection is important to us. All partners are subject to strict non-disclosure agreements (NDA) to protect your intellectual property and keep your purchasing conditions confidential.

Secure data transmission

Your data is transmitted end-to-end encrypted to our servers in Germany. You alone decide whether data remains on our servers after production.

Anonymised production drawings

We remove any information about you or your company on all documents before we share them with our partners for production.