Framework agreements

Reliable planning security for your components

Cost security through a fixed framework agreement

Would you like to guarantee stable purchasing conditions for your components in the long term? A framework agreement offers protection against rising material costs and possible delivery failures. Even when there is time pressure, we ensure compliance with your procurement processes and promote efficient procurement procedures.

Through our global network, we always find the optimal supplier for your components. Secure the best conditions for tomorrow’s components today.

Supplier selection

The right supplier for your components

For framework agreements, we only consider suppliers with an excellent Streametal Supplier Score. Based on a variety of criteria, we select the most suitable producer for each component. This supplier must not only master the desired material and the corresponding manufacturing process, but also have expertise in the desired surface finishing. In addition, he must offer the necessary capacities for your planned call-off frequency.

To ensure consistent quality, the selected supplier remains constant throughout the entire contract period. However, should a supplier failure occur, we will provide an equivalent replacement in our network. Thanks to double quality control by the suppliers and Streametal, you always receive consistent quality.

Please let us know if special certifications are required for your components. We will gladly take these requirements into account when selecting a supplier.

Haben Sie Fragen zu Rahmenverträgen?

In this way we guarantee the protection of your data.

Security = Streametal

Non-Disclosure Agreement (NDA)

Secure data transmission

Anonymised production drawings

Our manufacturing processes

From prototype development to series production – Streametal makes this process possible!

Turning

Milling

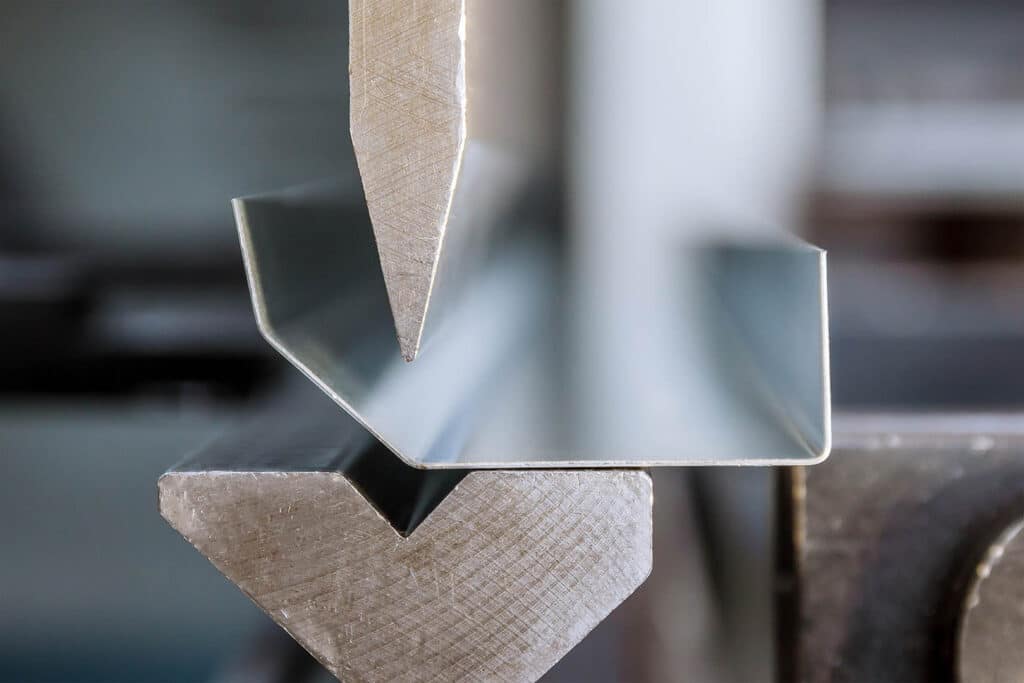

Bending

Punching

Laser cutting

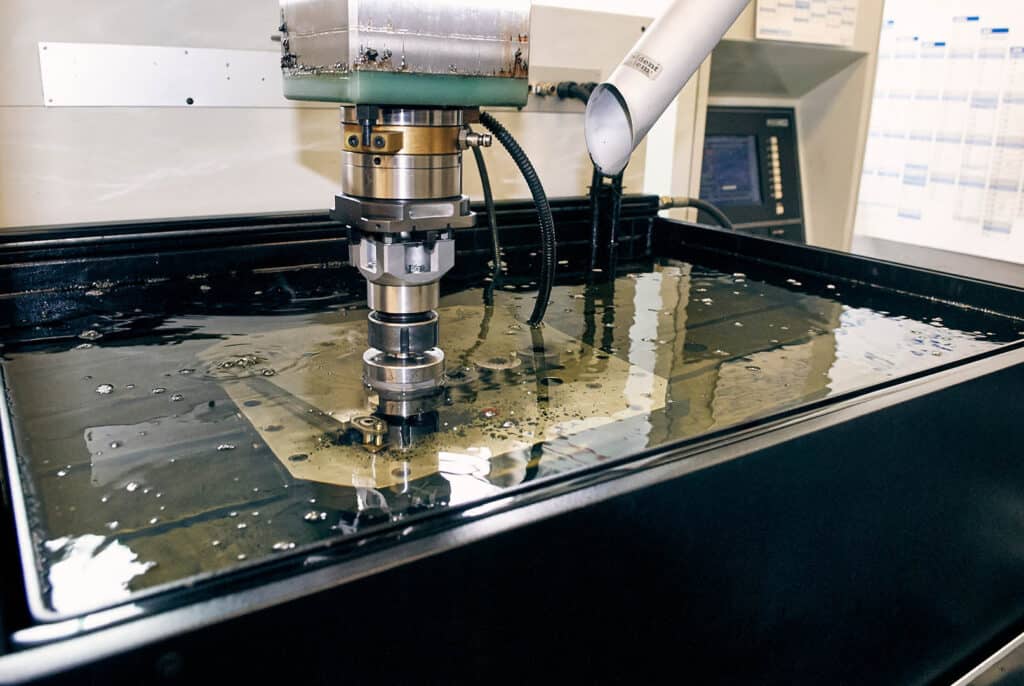

Water jet cutting

Eroding

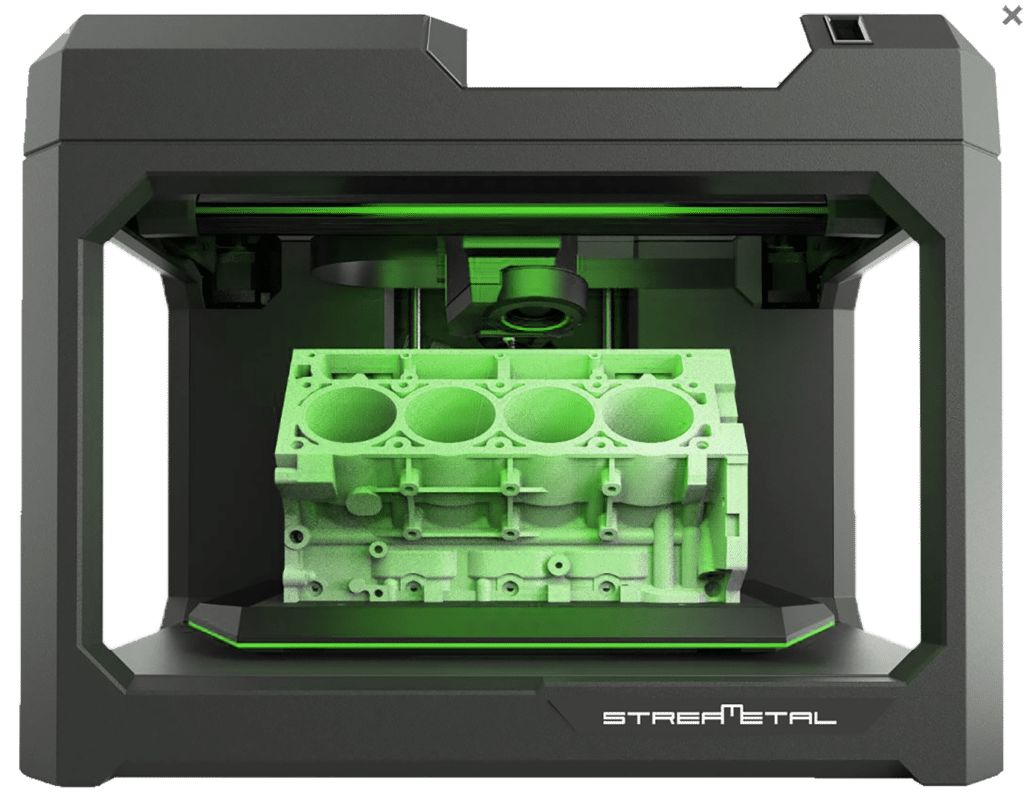

3D printing

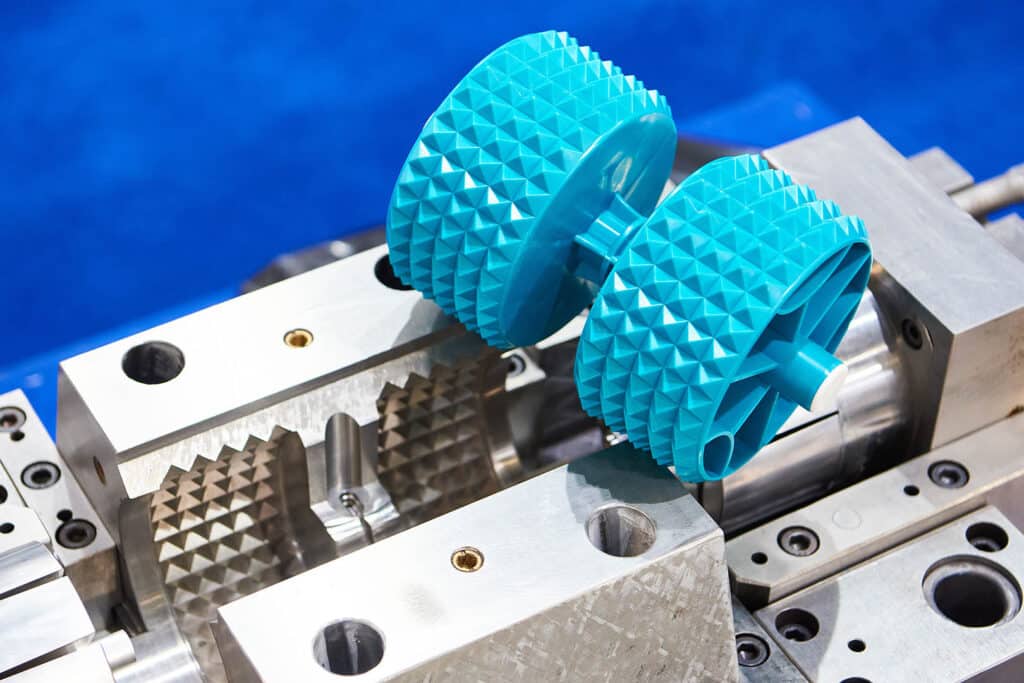

Injection moulding

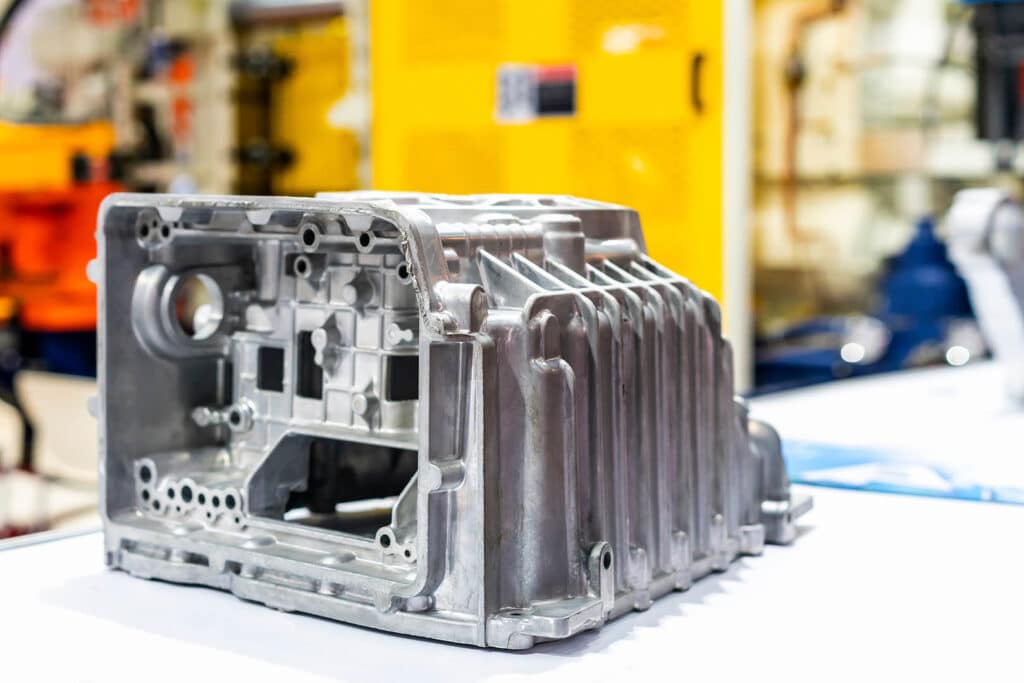

Die casting

Surface treatment